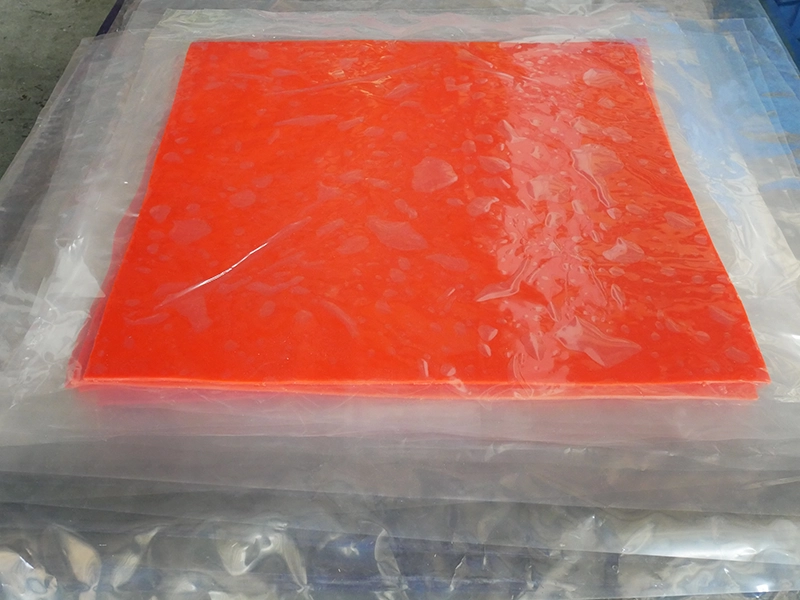

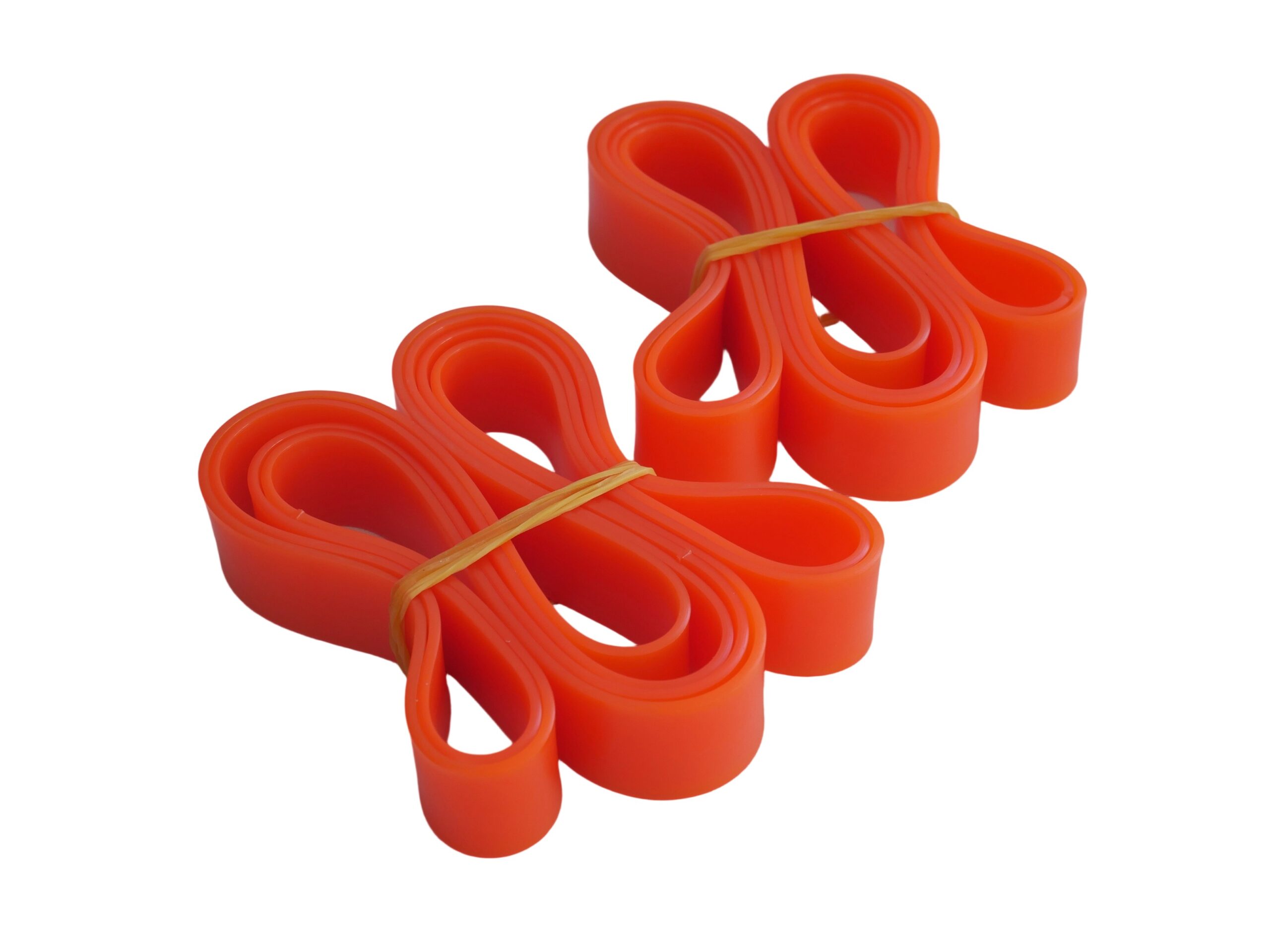

- Specially formulated polyurethane used to withstand the rigors of plowing with exceptional abrasion resistance.

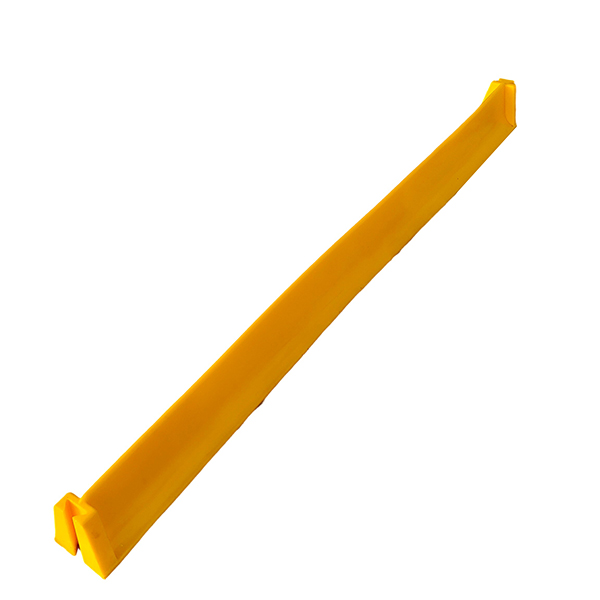

- Our polyurethane snow blades use a UV-resistant formula—no fading or hardening under direct sunlight (vs. standard urethane)

- Quality inspection for crack, bubbles and tear for each polyurethane snow plow blades

- Design and technical support

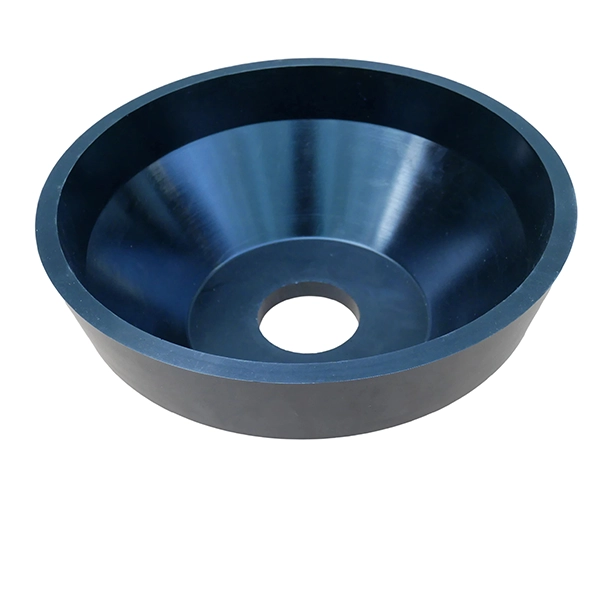

- Urethane blends resists oils, chemicals, and extreme temperatures

- Relative low tooling cost

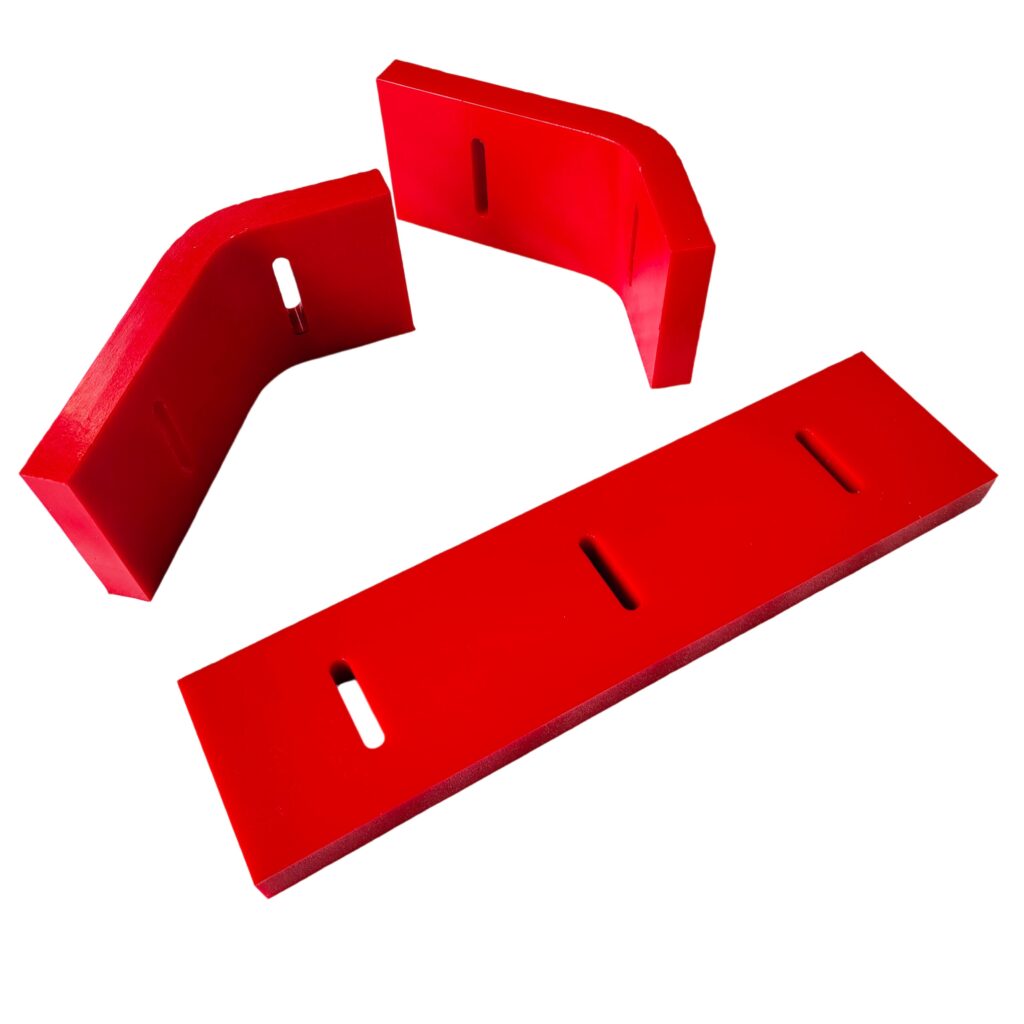

- Polyurethane snow plow blades can be purchased in customized hardness ,lengths, widths and thicknesses.

- Free hardness and formulation selection guide for polyurethane plow cutting edge included with every order