Extremely Abrasion-Resistant Polyurethane Rubber Formulas: Custom Cast Solutions for Mining & Logistics Applications

What Are Extremely Abrasion-Resistant Polyurethane Rubber Formulas?

Extremely abrasion-resistant polyurethane rubber refers to custom cast polyurethane formulations engineered for extreme wear applications such as mining, quarrying, and warehousing logistics where conventional polyurethane rubber fail to withstand persistent friction, sharp impacts, and heavy loads. Unlike standard injection-molded TPU or generic polyurethane rubber, these high-performance formulas are mixed and reacted via a prepolymer casting process using MDI/NDI isocyanates, reinforced with functional fillers (ceramic microbeads, graphene, or silicon carbide), and optimized with polyester/polyether/PCD/PCL polyols for targeted durability .

The molecular structure forms a dense covalent cross-linked network, a hallmark of cast polyurethane that delivers superior abrasion resistance compared to thermoplastic alternatives. As a custom cast manufacturer, our formulas are not one-size-fits-all: we tailor raw material ratios, filler content, and hardness (70A–98A Shore) to address the two primary wear types in mining/logistics—abrasive wear from sharp ore particles and compressive wear from heavy equipment rolling . All formulas comply with ASTM D4060 (wear resistance) and ISO 4649 (compression set) standards, with Taber abrasion indexes as low as 45 mg/1000 rotations with 3–5 times better than natural rubber . This customization capability sets them apart from off-the-shelf polyurethane rubber, making them indispensable for non-standard mining and logistics equipment.

Key Properties of Extremely Abrasion-Resistant Polyurethane Rubber Formulas

The superiority of these formulas lies in their balanced performance, validated by third-party testing and field applications, which directly solves the pain points of mining and logistics operations. Each property is engineered to exceed generic elastomers in harsh, high-wear environments:

Low noise & floor protection: Logistics-focused formulas feature low rolling resistance (≤0.028) to reduce AGV energy consumption and non-marking surfaces that protect epoxy warehouse floors—critical for automated facilities .

Exceptional abrasion resistance: Tested via ASTM D4060 (CS-17 wheel), our formulas achieve wear loss ≤20 mg after 1000 rotations, with an Akron abrasion value below 0.03 cm³/1.61 km—meeting the highest industrial grade . This outperforms standard polyurethane rubber by 2x and natural rubber by 4–5x, drastically reducing part replacement frequency.

High hardness & load-bearing capacity: Tuned to 90A–98A Shore hardness, the formulas balance rigidity and elasticity. Mining-grade variants (95A–98A) withstand 20+ ton single-wheel static loads, while logistics formulas (90A–92A) maintain low compression set (≤8.5%) to avoid permanent deformation under AGV/forklift loads .

Superior bonding & tear strength: After sandblasting and primer coating, bonding strength with metal cores exceeds 10 MPa preventing delamination in continuous operation . Tear strength reaches 80–120 kN/m, ensuring cracks from sharp ore or cargo edges do not propagate.

Environmental adaptability: Polyester-based formulas resist mineral oil and solvents (ideal for mining equipment), while polyether-based options offer hydrolysis resistance for humid logistics warehouses . All formulas operate stably from -40℃ to 120℃, avoiding brittleness in cold mines or softening from friction heat.

Industry Applications: Mining & Quarrying + Warehousing & Logistics

Extremely abrasion-resistant polyurethane rubber formulas are tailored to the unique operational demands of mining/quarrying and warehousing/logistics. We deliver end-to-end custom solutions, from formula design to mold development, with each application optimized for maximum service life and efficiency:

Mining & Quarrying Applications

Mining and quarrying face extreme abrasion from sharp ore, heavy dynamic loads, and harsh outdoor/underground conditions—our formulas address these challenges with specialized designs:

- Polyurethane Friction Drive Wheels for Mining Crane Suspended Monorail Systems: High performance NDI-based polyurethane tire provides 5x longer life than common polyurethane wheels for mining monorails . Flame-retardant & anti-static: Meets coal mine safety standards .

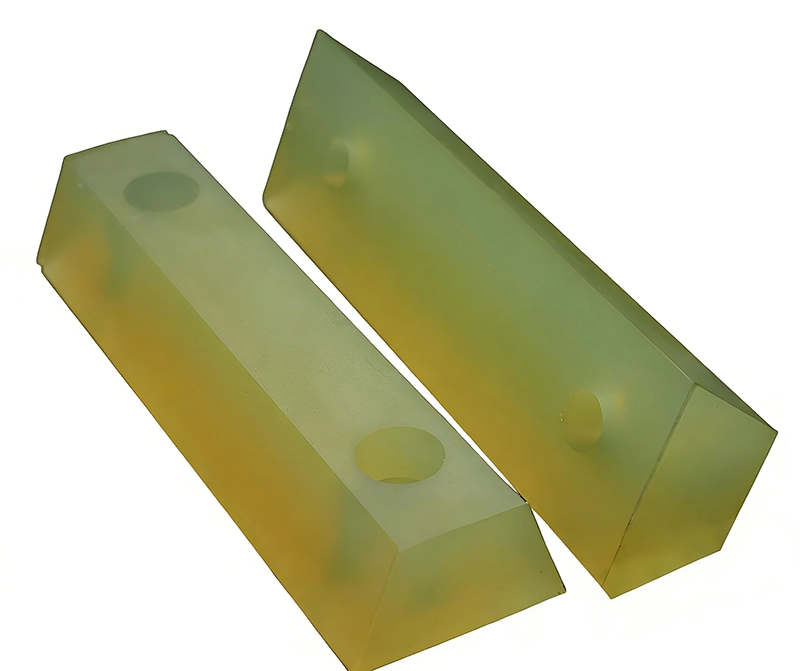

- Mine cart wear liners (95A–98A Polyester-MDI Formula): Reinforced with 5% silicon carbide filler, this formula resists abrasive wear from ore fragments, extending liner life to 8x that of steel and 4x that of natural rubber . It absorbs impact to reduce mine cart vibration, protecting track infrastructure from premature damage.

- Roadheader PU-coated wheels (90A–92A Polyether-MDI Formula): Hydrolysis-resistant and impact-absorbent, this formula withstands wet underground environments and sharp rock impacts. It avoids wheel cracking and delamination, ensuring continuous tunneling operations with minimal downtime.

- Ore hopper anti-wear linings (93A–95A Nano-Modified Formula): Blended with 3% nano-silica, this formula enhances wear resistance while reducing material flow resistance—preventing ore buildup and blockages. It eliminates metal-to-metal contact, reducing corrosion and noise in quarry processing plants.

Warehousing & Logistics Applications

Automated logistics and heavy-duty material handling demand abrasion resistance, precision, and low noise—our formulas balance these properties for core equipment:

- Forklift tire PU coating (91A–93A Formula): The non-marking surface protects warehouse floors, and its abrasion resistance doubles service life compared to standard rubber tires.

- AGV and RGV heavy-duty drive wheels (90A–92A NDI/MDI Hybrid Formula): This high-performance blend delivers 5000-hour continuous operation with only 0.18 mm wear loss (well below the industry average of 0.35 mm) . Low rolling resistance cuts AGV and RGV energy consumption by 12%, making it ideal for smart warehouse fleets.

- Conveyor roller polyurethane coating (92A–94A Polyester Formula): Tear-resistant and oil-proof, this formula adheres tightly to steel cores, preventing peeling in high-speed logistics lines. It reduces conveyor belt friction, extending both roller and belt service life in pallet/carton handling operations.

Extremely Abrasion-Resistant Polyurethane Rubber vs. Competitor Materials

For mining and logistics professionals, selecting the right wear-resistant material requires balancing performance, cost, and service life. Based on field data and total cost of ownership (TCO) analysis, our extremely abrasion-resistant polyurethane rubber outperforms alternatives in key metrics:

| Material Type | Abrasion Resistance (Taber Index) | Service Life (Mining/Logistics) | Annual Maintenance Cost | Customization | 1-Year TCO (Relative) |

|---|---|---|---|---|---|

| Extremely Abrasion-Resistant Cast PU Rubber | 45–60 mg/1000 rotations | 12–24 months | Low (1–2 replacements/year) | Full (hardness, fillers, shape) | 1.0 (Baseline) |

| Standard Polyurethane Rubber | 80–100 mg/1000 rotations | 6–8 months | Moderate (3–4 replacements/year) | Limited (60A–85A only) | 1.8 |

| Natural Rubber | 200–250 mg/1000 rotations | 3–4 months | High (monthly replacements) | Minimal (fixed formula) | 3.2 |

| Nylon/Plastic | 70–90 mg/1000 rotations | 6–7 months | High (brittle in cold/mining) | No (standard molds) | 2.1 |

| Metal (Steel/Alloy) | 30–40 mg/1000 rotations | 18–24 months | Moderate (corrosion repair) | No (machined only) | 2.7 |

Competitive Edge: Unlike rigid metal (high noise/corrosion) or brittle nylon, our polyurethane rubber combines the hardness of engineering plastics with rubber’s elasticity, absorbing impact and reducing equipment vibration . While metal offers similar wear resistance, our custom cast solutions are 30% lighter and reduce noise by 40%—critical for underground mining and indoor logistics . Compared to natural rubber, the higher upfront cost is offset by 60% lower annual maintenance expenses .

FAQs About Extremely Abrasion-Resistant Polyurethane Rubber Formulas

We’ve compiled the most pressing questions from mining/logistics procurement managers, design engineers, and technical staff. Answers based in 20+ years of custom casting experience and 2025 industry standards:

Q: What is the lead time for custom parts?

A: Samples: 3–5 working days. Small-batch orders: 7–10 days. Bulk orders (1000+ units): 15–30 days. Urgent 48-hour turnaround is available for critical mining/logistics parts.

Q: What Shore hardness is best for mining vs. logistics applications?

A: Mining/quarrying (ore hoppers, roadheaders): 93A–98A (high hardness for sharp impacts). Logistics (AGVs, conveyors): 90A–92A (balances wear resistance and shock absorption). We provide free hardness testing for your equipment.

Q: Polyester vs. polyether—how to choose for my operation?

A: Polyester formulas (95A–98A) excel in oil resistance and abrasion—ideal for mining equipment exposed to mineral oil. Polyether formulas (90A–92A) offer hydrolysis resistance for humid warehouses or outdoor quarries .

Q: Can you customize formulas for non-standard mining/logistics equipment?

A: Yes. We optimize formulas using your equipment drawings, load capacity, and wear sources (e.g., 5% silicon carbide for ore liners). No MOQ for custom molds, with 3–5 day sample lead times.

Q: What testing validates abrasion resistance?

A: We conduct ASTM D4060 Taber abrasion tests, Akron wear tests, and on-site trials (30-day mining/1000-hour logistics). Third-party SGS reports confirm wear performance and bonding strength (≥10 MPa) .

Q: What certifications do your formulas hold for international clients?

A: All formulas meet ASTM D4060, ISO 4649, RoHS(EU), and FDA (US) standards.

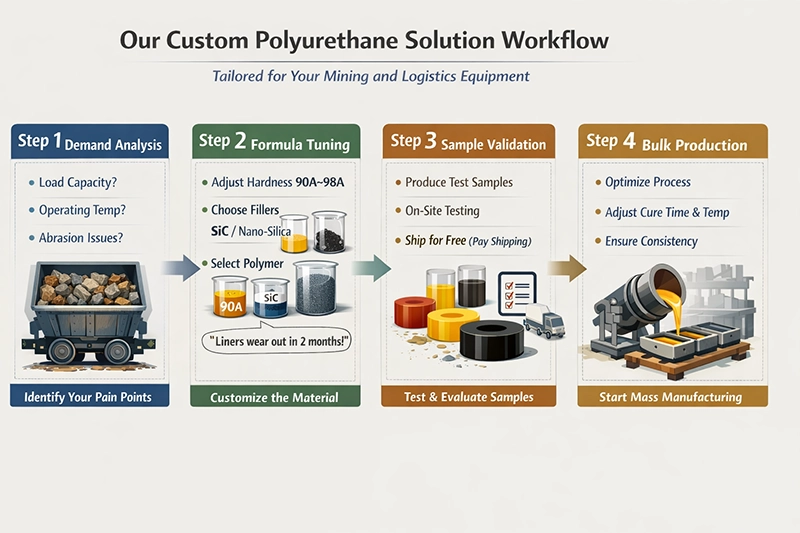

Formula Design Workflow for Mining & Logistics High-Wear Polyurethane Rubber Applications

As a custom molded polyurethane products manufacturer, we don’t offer “off-the-shelf” high-wear formulas — we follow a 4-step design workflow to match formulas to your mining/logistics equipment’s unique pain points. This workflow is tailored for non-standard equipment (e.g., custom mine cart liners, AGV wheels with special treads) that generic suppliers can’t support.

Step 1: Demand Analysis — Collect your equipment parameters (load capacity, operating temperature, abrasion source) and pain points (e.g., “chute and hopper liners wear out in 2 months”).

Step 2: Formula Tuning — Adjust hardness (90A–98A), filler type (silicon carbide for mining, nano-silica for logistics), and polymer base (polyester for oil resistance, polyether for hydrolysis resistance).

Step 3: Sample Validation — Produce 2-3 formula samples for your on-site testing.

Step 4: Bulk Production — Optimize casting process (curing time, temperature) based on sample feedback to ensure consistency.

For example, a Australian quarry needed liners resistant to 100mm sharp ore impact . We adjusted the formula to 97A with 4% silicon carbide filler, extending liner life from 2 months to 14 months. This workflow ensures 100% formula compatibility with your equipment.