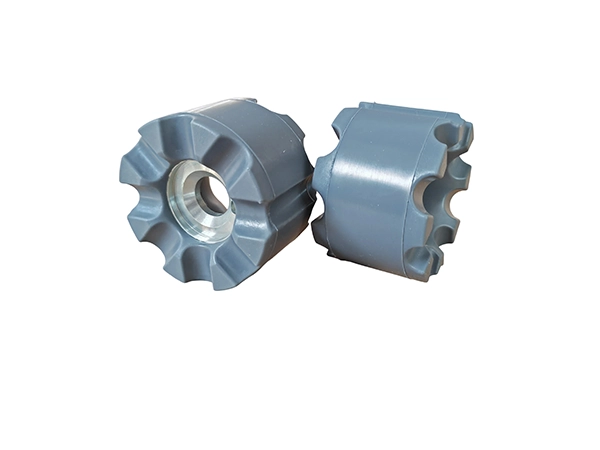

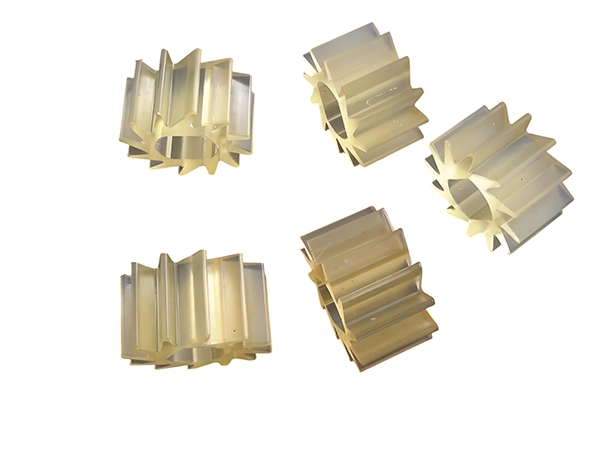

Custom Cast Urethane Spring Spacers — Durable Lift & Suspension Solutions

- Durable polyurethane coil spring spacers provide stable lift without compromising ride quality.

- Custom cast urethane spring spacers engineered to fit specific vehicle coil diameters.

- Polyurethane spring spacers resist compression set and weathering for long-term performance.

- Easy installation between coil springs increases ground clearance for off-road applications.

- Superior load-bearing capacity compared to rubber spacers for trucks and SUVs.