Become a Global Solution Partner for China-Made Custom Casting Molded Polyurethane Products – Partner with PEPSEN

About Shanghai Pepsen

Founded in 2004 and located in Shanghai, with easy access to oversea logistics networks. Shanghai Pepsen is a leading China-based manufacturer specializing in R&D, production, and sales of high-performance custom molded polyurethane rubber products . Backed by over 20 years of industry expertise, we’ve built a comprehensive system covering formula development, precision manufacturing, and quality control, and with 30+ invention and utility patents .

Our 100-strong team operates advanced facilities: a testing center, analytical laboratory, prototyping workshop, and large-scale production lines. We strictly comply with environmental regulations, safety standards, and occupational health requirements, while serving both domestic key projects and Fortune 500 enterprises worldwide . Our mission is to deliver durable, application-specific polyurethane solutions that replace traditional materials and optimize our clients’ operations.

Types of Casting Molded Polyurethane Product Series

Polyurethane Rollers

- Abrasion-resistant, elastic, and stable—outperforms rubber/metal rollers.

- Key applications: Pipe conveyor polyurethane V grooved rollers (oil & gas), conveyors (mining/food), polyurethane drive rollers (material handling),polyurethane idler rollers, high performace NDI-based polyurethane rollers ,mecanum wheels for AGV

- Customizable: 20–2000mm diameter, Shore 20A–95A-80D hardness.

Polyurethane Wheels

- Heavy-load bearing, low noise, and corrosion-resistant—ideal for harsh use.

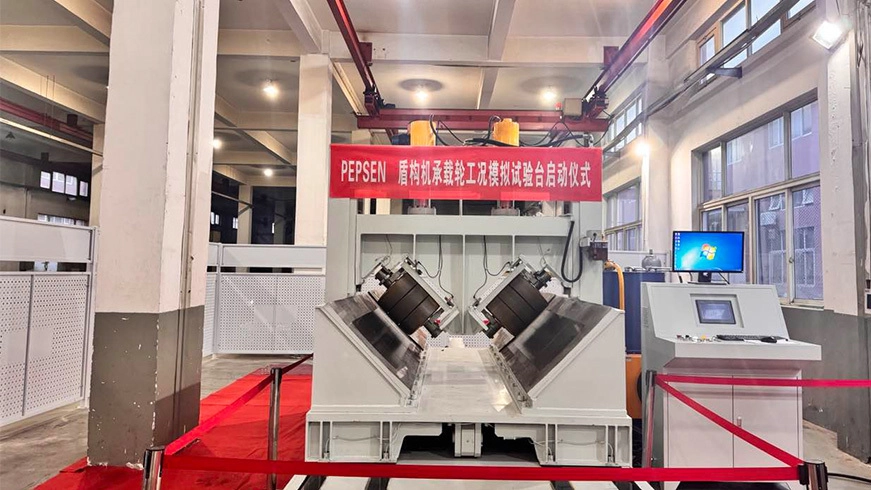

- Key applications: Polyurethane drive wheels (warehouse logistics), NDI-based polyurethane Wheels for AGV, skid conveyor roller wheel for electric automobile assembly line, wheels for floor scrubbers dryer/drier, NDI-based polyurethane polyurethane friction drive wheel for monorail transport systems, polyurethane press-on tires/wheels for shield tunnelling

- Customizable: 20–300mm wheel diameter, metal-core (carbon steel/304 SS) options.

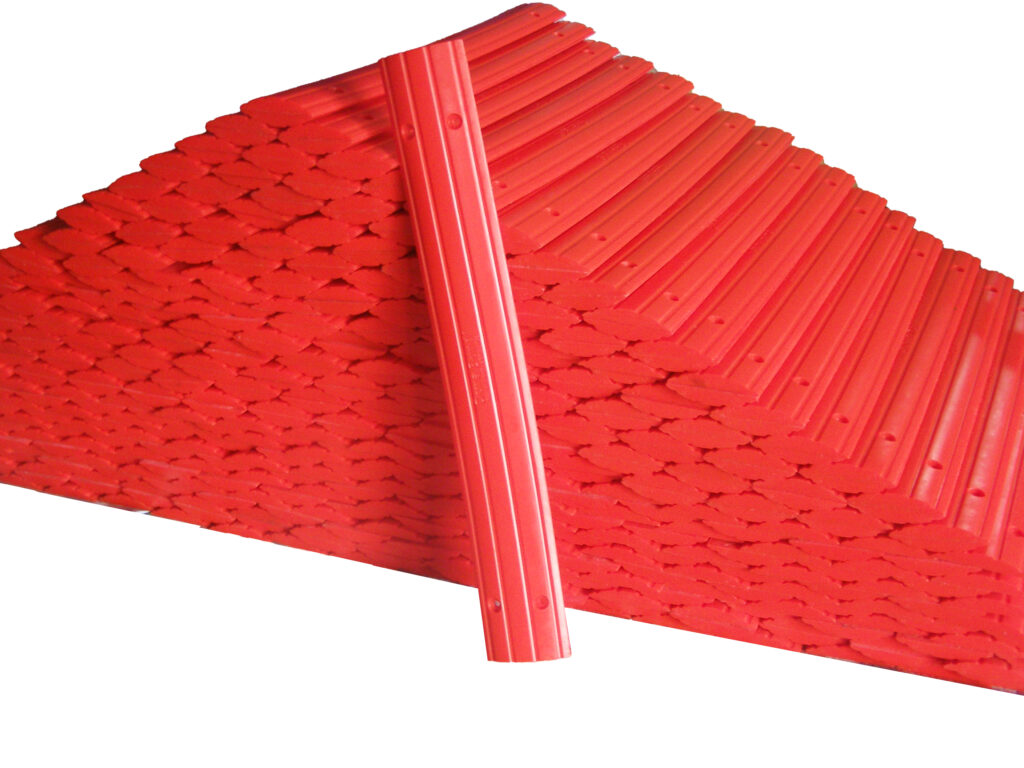

Polyurethane Linings

- Abrasion and scratch resistant—protects equipment inner surfaces.

- Key applications: Hooper Lining (grain/coal), pipelines and valve (chemical transport)

- Customizable: 5–500mm thickness, chemical-resistant formulations available.

Custom Polyurethane Parts

- Molded parts (gaskets, seals, bushings) for automotive, oil & gas, and construction.

- Urethane overmolded parts (urethane on metal/plastic/rubber) for structural stability in harsh conditions.

Key Technical Advantages

- Proprietary Formula R&D: Custom polyurethane blends for specific needs, such as abrasion and impact resistance, chemical resistance (acids/caustics), or high-temperature .

- Precision Bonding Technology: Expert urethane-metal bonding ensures no delamination, even under continuous stress (tested to 10,000+ cycles of impact).

- Strict Quality Inspection: Every part/batch undergoes hardness , surface finish and dimensional accuracy tests .s.

Industry Applications

- Mining & Construction: Abrasion-resistant conveyor belts scraper blades for gravel/coal handling.

- Food Processing: FDA-approved belts and blades for dough, dairy, and beverage lines.

- Logistics & Automation: Rollers/wheels for warehouse forklifts and AGVs.

- Packaging: No Crush wheel / roller, bottle capper inserts & tightening discs.

- Automotive: Polyurethane bushings, urethane engine mount.

Customization Services

| Customization Parameter | Options & Capabilities | Turnaround Time |

|---|---|---|

| Material Blend | Standard/Abrasion-Resistant/Chemical-Resistant/Food-Grade | 1–2 days (formula finalization) |

| Dimensions | Up to 4000/2000mm (length/width); 0.5–500mm (thickness) | 7–14 days (molding/production) |

| Hardness | Shore 0A-98A-80D | Same as production |

| Surface/Edge Design | Smooth/Grooved/Beveled/Rounded; Color-coding | Included in production |

| Physical properties testing | Tear strength/tensile strength/abrasion loss and etc | 7 days |

| Certification | Inspection report , material certificates | 1 day before delivery |

Customer Cases & Certifications

- Global Clients: Partnered with world-leading mining firms and logistics manufacturers (e.g., largest airport belt curve conveyor in USA, mining operators in Australia).

- Key Projects: Supplied custom polyurethane wheels for China’s Railway Construction Cooperation.

- Certifications: ISO 9001, RoHS, and environmental safety approvals .

FAQs

- Q: What’s the lifespan of your polyurethane products vs. rubber?A: 3–5x longer lifespan, with scraper blades lasting 12+ months in heavy mining use.

- Q: Can you provide samples before mass production?A: Yes—custom samples delivered in 7–10 days, with sample costs deductible from bulk orders.

- Q: Do you offer after-sales support?A: 24/7 technical support, plus 12-month warranty for manufacturing defects.

For custom polyurethane solutions, contact our team via www.pepsenpu.com or email sales@pepsenpu.com.