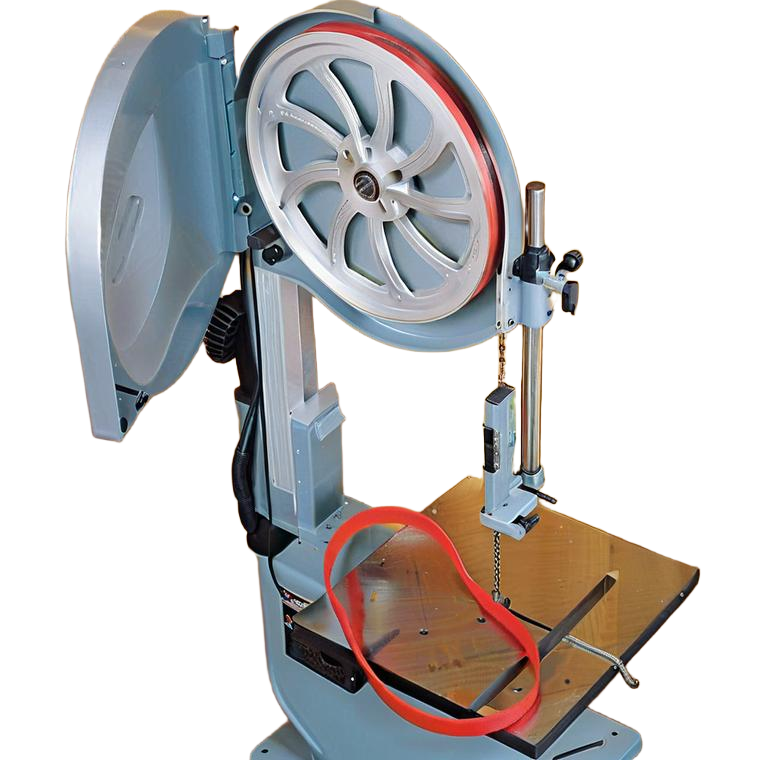

Bandsaw Tires That Outlast and Outperform

- Durable urethane for long - lasting use

- Perfect fit for 12 - inch and 14 - inch saws

- MOQ=500pcs

- Durable urethane for long - lasting use

- Perfect fit for 12 - inch and 14 - inch saws

- MOQ=500pcs

We are China's manufacturer of custom urethane bandsaw tires with or without seam . Our branded (BASF )material and experienced workers make sure each tire can meet the high quality and performance. Hardness , dimensions, shape and colors can be customized with MOQ=500pcs.

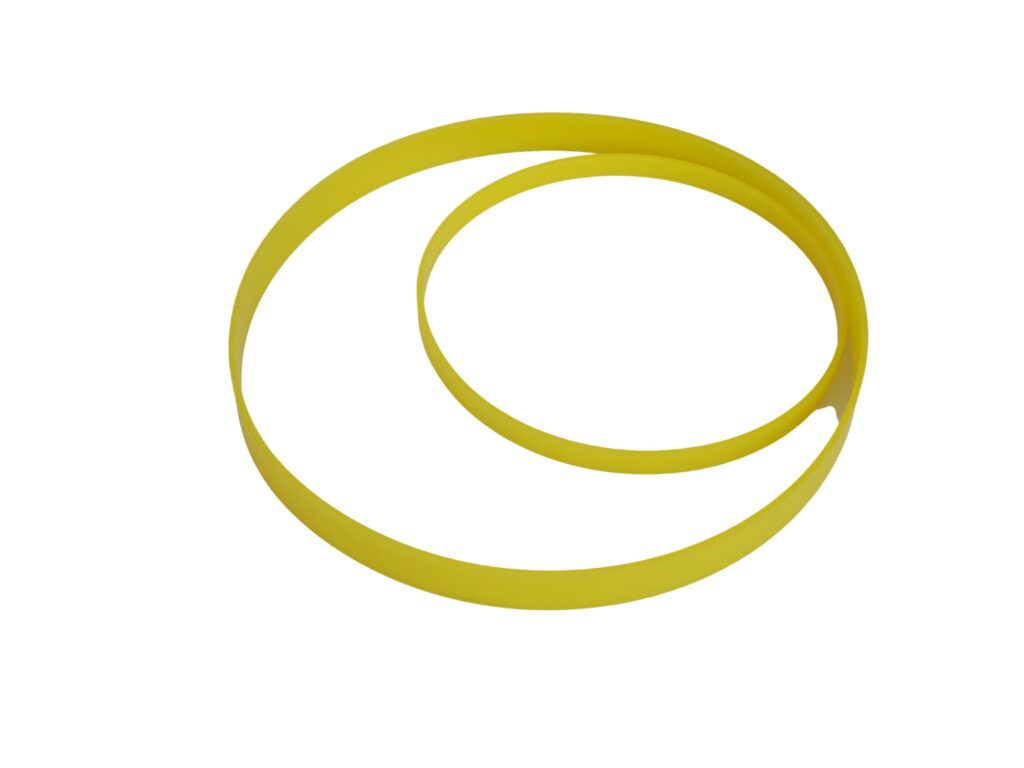

Our urethane bandsaw tires offer durability. They outlast traditional rubber tires by a significant margin, resisting drying out, cracking, and hardening. These tires provide a superior grip, which results in better blade tracking and reduces the risk of blade damage. They also come in a bright, visible color for easy inspection.

These tires are widely used in various industries. In woodworking shops, they are crucial for achieving clean, precise cuts. Metalworking industries benefit from their ability to handle the high - stress demands of cutting metals. Hobbyists and DIY enthusiasts appreciate their easy installation and long - lasting performance.

| Items | Ranges | Application/Advantages |

|---|---|---|

| Hardness | 70A (soft) – 98A (medium) | Woodworking (80A for general use), metalworking (90A for more abrasive metals) |

| Size | Diameters: 6 - 30 inches(no limit); Widths: 0.5 - 1.5 inches | Woodworking band saws (12 - 14 inch common), metal - cutting band saws |

| Color | Standard orange, custom colors available | For easy identification in industrial settings, color - coded for different applications |

| Seam or seamless | Seam one by injection TPU Seamless one by casting PU | Seam one : common quality , less expensive and tooling fee, with size limitation Seamless one : super quality , sligtly more expensive , no size limitation |

| Stocked tools | 8 inch , 9 inch, 12 inch , 14 inch, 16 inch, 18 inch, 22 inch | MOQ=500pcs |

- Woodworking for smooth, accurate cuts

- Metalworking to handle tough materials

- Hobbyist projects for reliable performance

- DIY workshops for long - lasting use

- Furniture manufacturing for precision shaping

- Craftsman band saws for enhanced functionality

1) Outlast rubber and plastic band saw tires

2) Resist dry rot

3) Require no adhesive for installation

4) The width can be trimmed to fit

5) Smooth contact surface for the blade

- BASF new raw material used

- Quality inspection for each tire

- Technical and design support

- FDA and RoHS Compliant.

- Flexible Customization

Rubber band saw tires are slightly more flexible while urethane ones in much more abrasion and tear resistance.

Urethane tires can be Installed easily without glue - simply stretch to fit .

Measure the wheel diameter ,width and thickness. Cut them off and measure the length can be more precise for manufacturing purpose.

Yes. We are manufacturer. Welcome to visit our factory.

Yes. The process includes Share needs → design & quote → prototype (opt) → production → delivery.

We have 10 inspectors to carry out raw material inspection, process control ,first article inspection and final inspection.

We use the ERP system to execute orders, and can check the order status and expected delivery time at any time.

All of products with 3-6 months guarantee (except very frequently wearing parts).

We will response in 24 hours with solutions such as replacement or reworking.

We have dedicated personnel to sort out and maintain molds regularly.

20,000 times for compressions molds and 30,000 time for casting molds

Due to the large quantity of molds, we can keep the molds for free for 2 to 3 years even if no order.

Customers only need to pay mold cost once. We will cover the cost if molds are damaged or reach the lifespan.

get a quote