Introduction

Molded polyurethane is a high-performance synthetic elastomer formed by the chemical reaction of polyurethane prepolymers and specialized curing agents engineered to balance flexibility, strength, and durability like no other material. Unlike rigid plastics or traditional rubber, it can be precisely molded into complex shapes, adjusted for hardness (from Shore OO to Shore D), and enhanced with additives to resist chemicals, UV, or microbes. For industrial manufacturers, engineers, and procurement teams, this versatility makes custom molded polyurethane the go-to choice for parts that need to withstand harsh condition from mining equipment to medical devices.

In this guide, we’ll break down what molded polyurethane is, its unrivaled benefits, how it’s customized for specific industries, and why it outperforms other materials. Whether you’re replacing worn parts or designing a new component, you’ll learn how our China-based manufacturing expertise delivers molded polyurethane solutions that meet your exact specs.

What Is Molded Polyurethane & How Does It Work?

Definition

Molded polyurethane (often called “urethane molding”) refers to the process of shaping liquid polyurethane resin into solid parts using molds, either via casting (for custom, low-to-medium volume parts) or injection molding (for high-volume precision components). The material’s molecular structure, made of flexible “soft segments” and rigid “hard segments,” gives it a unique blend of rubber-like elasticity and plastic-like strength.

Key Manufacturing Processes

While there are several molding methods, two dominate industrial applications—both tailored to different production needs:

- Cast Molded Polyurethane: Liquid resin is poured into a custom mold, then cured at room temperature or in industrial ovens. Ideal for complex shapes, large parts (e.g., mining screen,forklift wheels), and low-to-medium volume orders. Our specialty lies here, with the ability to adjust formulations for niche requirements (e.g., anti-static, hydrolysis-resistant).

- Injection Molded Polyurethane: Molten resin is injected into a mold under high pressure, enabling fast production of small, precise parts (e.g., automotive bushings, medical seals). Best for high-volume runs where consistency and speed are critical.

Both processes leverage polyurethane’s inherent adaptability. We can tweak everything from hardness to chemical resistance to match your equipment’s unique demands.

Key Benefits of Molded Polyurethane for Industrial Use

Molded polyurethane stands out from rubber, plastic, and metal because it solves the “compromise problem” common in other materials. Here’s why it’s trusted across industries:

Easy Integration: Bonds seamlessly to metals, glass, or plastics, eliminating the need for additional fasteners (e.g., coated conveyor belts, bonded bushings).

Flexible Customization: Adjust hardness (20 Shore A to 80 Shore D), add additives (anti-static, flame-retardant, anti-bacteria), or modify dimensions (from tiny washers to 100+ pound rollers) to fit your exact needs.

Superior Durability: Outlasts rubber by 3x in high-wear applications (e.g., conveyor rollers) and resists abrasion, oils, and solvents even in humid or high-temperature environments (-40°C to 120°C for standard grades).

Cost-Effective: Lower tooling costs than metal or plastic molding, plus longer part life reduces replacement frequency. For example, our molded polyurethane mining screen cuts maintenance costs by 40% vs. rubber alternatives.

Excellent Mechanical Performance: Combines high tensile strength (up to 50 MPa), low compression set (≤15% after 72 hours), and impact resistance—ideal for dynamic load applications like vibration dampeners or forklift wheels.

Custom Molded Polyurethane: Tailored to Your Industry Needs

Molded polyurethane isn’t a “one-size-fits-all” material. It’s engineered to solve industry-specific challenges. Below are the most common applications, with our custom solutions:

1. Industrial Manufacturing

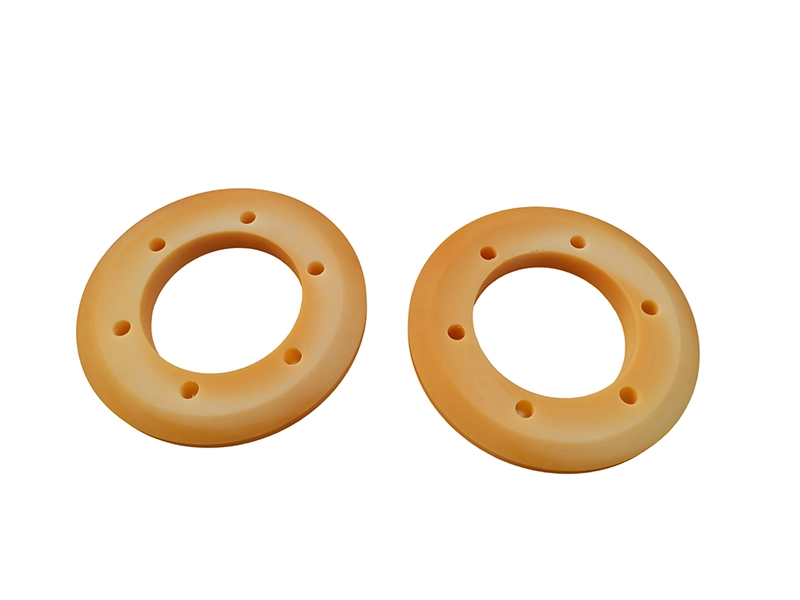

Parts: Conveyor rollers, machine bushings, seal gaskets, and bumper pads.

Customization: Add anti-static additives for electronics assembly lines, or high-wear formulations for heavy-duty conveyor systems.

Why It Works: Resists oils and coolants, reduces equipment vibration, and maintains performance in 24/7 production environments.

2. Mining & Heavy Industries

Parts: Food-grade conveyor rollers, equipment seal gaskets, and transfer line guide wheels.

Customization: Antimicrobial additives prevent mold growth in humid mines; hydrolysis-resistant formulas withstand water exposure; high-durometer (90 Shore A) grades handle sharp rock abrasion.

Case Example: Our molded polyurethane mining screen lasted 18 months vs. 6 months for rubber—cutting downtime by 60%.

3. Food Processing & Beverage

Parts: Prosthetic components, medical device gaskets, and surgical tool handles.

Customization: FDA/EC 1935/2004 compliant formulations, non-toxic/non-migration resins, and smooth surfaces for easy sanitization.

Why It Works: Meets strict food safety standards, resists acidic/alkaline cleaners, and avoids contaminating edibles during production.

4. Automotive & Traffic

Parts: Suspension bushings, tire treads, rail pad insulators, and door seals.

Customization: Flame-retardant grades (meets UL94-V0) for electronics, and vibration-dampening formulas to reduce noise in high-speed trains.

Why It Works: Withstands road salts, extreme temperatures, and constant impact—extending vehicle/component life.

5. Renewable Energy

Parts: Wind turbine blade protectors, solar panel mounting gaskets, and hydroelectric seal components.

Customization: UV-stabilized resins for outdoor exposure, and hydrolysis-resistant grades for underwater applications.

Why It Works: Maintains performance in harsh weather (snow, salt spray) and reduces maintenance for remote energy sites.

Molded Polyurethane vs. Other Materials: Why It’s the Better Choice

Many industries default to rubber, plastic, or metal—but molded polyurethane offers a better balance of performance and cost. Here’s how it compares:

| Material | Key Advantage | Key Disadvantage | Molded Polyurethane |

|---|---|---|---|

| Natural Rubber | High flexibility | Poor chemical/oil resistance; short life | 3x longer wear life + resists oils/solvents |

| Rigid Plastic | Low cost for high-volume runs | Brittle; low impact resistance | Better impact absorption + customizable hardness |

| Metal | High strength | Heavy; prone to corrosion; noisy | Lighter (50% vs. steel) + corrosion-resistant + quiet |

| EPDM Rubber | Good weather resistance | Low tensile strength; slow to mold | Higher strength + faster custom molding lead times |

Our Custom Molded Polyurethane Process: From Concept to Delivery

As a trusted China manufacturer and supplier of custom molded polyurethane, we follow a rigorous, customer-centric process to ensure your parts meet every specification:

- Needs Assessment: Our engineers collaborate with you to define requirements—application environment (temperature, chemicals), load capacity, dimensions, and compliance standards (e.g., FDA, UL94-V0).

- Formula Design: We adjust polyurethane prepolymers, curing agents, and additives (e.g., anti-static, antimicrobial) to match your performance goals. For example, we’ll use polyester-based PU for hydrolysis resistance or polyether-based PU for low-temperature flexibility.

- Prototype & Testing: We produce small-batch samples (with fast 2–3 week lead times) for fit and performance testing. This step ensures no surprises before full production.

- Molding & Quality Control: Parts are cast or injection-molded using precision tools. Our 10-person QC team checks raw materials, in-process parts, and final products for dimensional accuracy (±0.05mm) and performance.

- Delivery & After-Sales Support: We ship globally (standard 4–6 week lead times for full orders) and offer a 3–6 month warranty. If issues arise, our team responds within 24 hours with solutions (replacement, reworking).

Case Studies: How Our Molded Polyurethane Solved Industrial Challenges

Case 1: Mining Operation Cuts Downtime with Wear-Resistant Polyurethane Scraper Blades

- Challenge: A South African underground mining firm struggled with frequent failures of their rubber conveyor scraper blades—wearing out in 3 months due to abrasive ore particles and humid (85%+ humidity) underground conditions. Frequent replacements caused 12+ hours of monthly downtime and inflated maintenance costs.

- Solution: We engineered custom molded polyurethane scraper blades with high-wear polyester-based PU (90 Shore A durometer) and added anti-tear reinforcing additives. The design was tailored to their conveyor system’s shaft diameter and ore throughput, ensuring tight contact with conveyor belts without damaging surfaces.

- Result: The polyurethane scraper blades lasted 9 months (3x longer than rubber), reduced monthly downtime by 80% (to 2 hours or less), cut maintenance costs by 45%, and maintained consistent ore transport efficiency even in high-humidity environments.

Case 2: Automotive Component Supplier Meets OEM Standards for Suspension Bushings

- Challenge: A European automotive OEM needed durable suspension bushings for heavy-duty trucks that could withstand high-frequency vibration, engine oil exposure, and -30°C to 120°C temperature swings—issues that made their previous rubber bushings fail in 6 months.

- Solution: We customized polyester-based molded polyurethane bushings with anti-aging additives, engineered to 85 Shore A durometer for balance of flexibility and rigidity. We tested samples to meet automotive standards (ISO 18797 for polyurethane automotive components) and verified oil resistance (ASTM D471) and vibration attenuation performance.

- Result: Bushings passed the OEM’s 500,000-cycle durability test, lasted 18 months (3x longer than rubber), reduced cabin vibration by 25%, and met the OEM’s global supply chain quality requirements.

FAQs About Molded Polyurethane

- What parameters can you customize for molded polyurethane parts? We adjust hardness (20 Shore A to 80 Shore D), dimensions (20mm–2000mm), color, additives (anti-static, flame-retardant), and core materials (steel, aluminum for structural support).

- What’s the lead time for custom molded polyurethane parts? Samples take 2–3 weeks; full production takes 4–6 weeks (expedited options available for urgent orders).

- Can your molded polyurethane withstand high temperatures or chemicals? Yes—standard grades work at -40°C to 120°C; specialized formulations handle up to 150°C. Our PU resists oils, acids, alkalis, and most solvents (ask for material compatibility charts).

- Do you offer samples before bulk orders?Absolutely, we provide 1–5 prototype samples for testing fit, performance, and compliance with your standards.

- Is your molded polyurethane compliant with industry regulations?Yes. We offer FDA-compliant grades for medical/food applications, UL94-V0 flame-retardant grades for electronics, and REACH-compliant formulas for global markets.

Contact us today to discuss your custom molded polyurethane needs. Our team will help design a solution that boosts your equipment’s performance, reduces maintenance costs, and fits your budget.