From Ultra-Soft Cushioning to Rigid Support, Cut $30k/Year Maintenance Costs

4 Industry Pain Points—You Need a "Precision Hardness Solution"!

Crushed flexible packaging during process, costing over $150k/year? Misaligned labels from inaccurate labeling machine positioning? Wasted raw materials due to leaking filling machines? Brittle support blocks reducing equipment accuracy? The root cause is "wrong polyurethane hardness"—only full-range coverage (Shore 0A to 80D) fits all scenarios: 0A for packaging cushioning, flexible labeling positioning and filling leak prevention, 98A for mining loads, and 80D for structural support. Choosing the right hardness doubles equipment lifespan and cuts 40% annual maintenance costs. This guide tells you: how to select from the full range, avoid testing pitfalls, and find custom solutions.

I. Detailed Full-Range Adaptation Table of Polyurethane Hardness (Industrial Products Only)

| Main Hardness Range | Sub-Hardness Range | Applicable Industrial Fields & Specific Equipment | Core User Benefits (Quantified Data) |

|---|---|---|---|

| Shore 0A–59A (Ultra-Soft to Soft, Focus on Packaging/Labeling/Filling Cushioning & Spill control) | Shore 0A–29A | 1. Packaging Industry: Film conveying cushions for food packaging machines, flexible pressure wheels for labeling machines (aluminum foil/plastic bags), scratch-proof buffer blocks for carton sealing machines 2. Filling Industry: Leak-proof sealing gaskets for filling machine nozzles (detergent/shampoo), buffer sleeves for beverage filling machine hose joints 3. Spill berm barrier , drain seans to prevent pollution | 1. Scratch Prevention: No scratches on flexible packaging materials, scratch rate ≤0.1% 2. Leak Prevention: Liquid leakage rate ≤0.01mL/h at 15% seal compression (suitable for water/daily chemical solutions) 3. Flexible Cushioning: Impact absorption rate ≥88%, no edge damage during labeling, labeling deviation ≤±0.5mm |

| Shore 30A–59A | 1. Packaging Conveying: Guide wheels for light packaging conveyors (small cosmetic/medicine boxes), soft diverters for e-commerce parcel sorters 2. Labeling Equipment: Pressure buffer wheels for bottle labeling machines (soy sauce/disfectant), soft pallets for label dispensers 3. Filling Auxiliary: Liner for anti-dripping troughs of pesticide filling machines, dust-proof buffer pads for lubricating oil filling nozzles | 1. Fatigue Resistance: Rebound rate ≥93% after 10,000 cycles of continuous labeling/filling, no permanent deformation 2. Stable Sealing: No leakage under 0.3MPa pressure, suitable for low-to-medium viscosity liquid filling 3. Media Resistance: No swelling after contact with pesticides/lubricating oil, volume change rate ≤1% | |

| Shore 60A–98A (Medium-Hard to High-Hard, Focus on Industrial Wear Resistance, Load Capacity & Quiet Operation) | Shore 60A–79A | 1. Industrial Logistics: Conveyor rollers for medium packaging (home appliance parts/auto small components), guide wheels for AGV packaging transport 2. Auto Parts Manufacturing: Buffer blocks for engine block conveying, positioning wheels for transmission assembly lines, pressure wheels for lamp module packaging machines 3. Textile Industry: Fabric guide wheels for high-speed weaving machines, tension adjustment pads for chemical fiber spinning equipment | 1. Quiet Operation: Working noise ≤52dB, meeting industrial workshop noise standards (GB/T 50087-2013) 2. Low Wear: Wear depth ≤0.6mm after 6 months of continuous operation, 50% more wear-resistant than ordinary rubber 3. Oil Resistance: Hardness change ≤±1A after contact with industrial lubricating oil/cutting fluid, no performance attenuation |

| Shore 80A–90A | 1. Heavy-Duty Logistics: Drive wheels for large packaging conveyors (washing machine/refrigerator casings), rollers for intelligent warehouse stackers 2. Construction Machinery: Pressure wheels for excavator spare parts packaging machines, buffer blocks for loader hydraulic pipelines, shock pads for roller instrument panels 3. Printing & Packaging Industry: Rubber rollers for corrugated printing machines (non-core), pressure wheels for heavy carton sealing machines | 1. Wear & Load Resistance: Withstands ≤2000N load, 6-month wear rate ≤7%, suitable for medium-sized industrial equipment 2. Impact Resistance: No cracks/permanent deformation after 80N instantaneous impact, suitable for bumpy working conditions 3. Weather Resistance: Performance attenuation ≤5% in -30℃~85℃ outdoor industrial environments | |

| Shore 91A–98A | 1. Mining & Heavy Industry: Drive wheels for mine belt conveyors, wear pads for ore sorters, buffer blocks for crusher feed inlets 2. Iron & Steel Metallurgy: Scrap conveyor rollers for steel mills, support wheels for steel cold rolling lines, wear pads for steel coil packaging pallets 3. Port Machinery: Guide wheels for container cranes, wear rollers for dock packaging cargo conveyors | 1. Heavy-Load Wear Resistance: Withstands ≤3500N static load, 6-month wear rate ≤4%, 30% lighter than steel wheels 2. Impact Crack Resistance: No visible cracks after 120N rock impact, suitable for harsh working conditions 3. Stable Friction: Surface friction coefficient 0.35±0.02, preventing conveyor belt slippage | |

| Shore 30D–80D (Rigid to Ultra-Rigid, Focus on Industrial Structural Support & High Strength) | Shore 30D–50D | 1. Industrial Equipment Structure: Support blocks for CNC machine tool bases, shock mounts for industrial robot bases, rack feet for automated packaging production lines 2. Pipeline Engineering: Sealing gaskets for industrial low-pressure pipelines (compressed air/cooling water), liner pads for chemical light-medium pipeline clamps 3. Tooling Fixtures: Positioning blocks for precision packaging machine tooling, support pads for welding fixtures | 1. Balanced Toughness & Rigidity: Compressive strength ≥65MPa, 4% elastic deformation to avoid rigid collision damage to equipment 2. Leak-Proof Sealing: Seal leakage rate ≤0.08kPa·L/s at 25% compression rate, meeting industrial pipeline requirements 3. Aging Resistance: Hardness attenuation ≤4% after 12 years of use in indoor industrial environments |

| Shore 51D–80D | 1. PUR damper for robotics protction 2. Pressure Roller: Presses paper to the final size. 3. High-elastic, wear-resistant Polyurethane bend restrictor limits hose/cable bend radius to prevent damage, ideal for harsh industrial use | 1. High-Strength Support: Compressive strength ≥105MPa, withstands ≤5000N static load (compliant with DIN 28084 standards) 2. Excellent dynamic performance, wear-resistant, stable hardness, hydrolysis-resistant. 3. Weather Resistance: No cracking/chalking after 6 years of use in outdoor industrial environments |

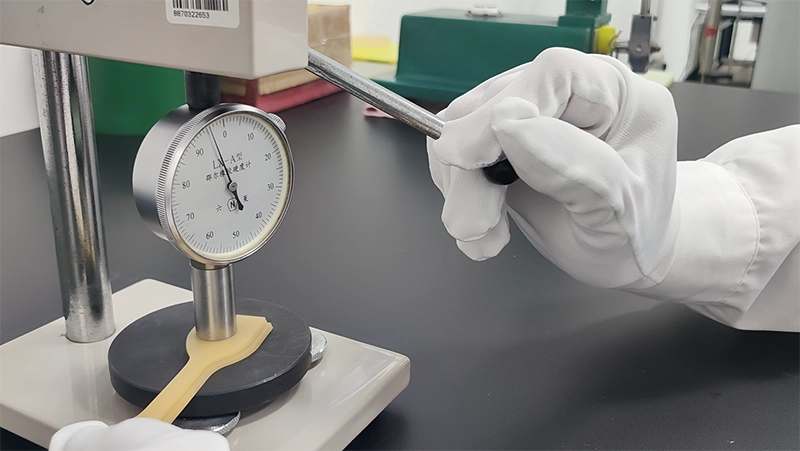

II. 4 Testing Pitfalls That Waste $15k—A/D Scale Guide

Mistakes in hardness testing often lead to mismatched parts—avoid these critical errors:

Pitfall 1: Testing thin samples (<6mm)

Outcome: Ultra-soft 0A-29A is crushed (false high reading), 80D rigid parts deform (false low reading), leading to premature failure in use.

Solution: Shore A samples ≥6mm, Shore D samples ≥10mm—match sample thickness to real working conditions.

Pitfall 2: Using Shore A durometer for Shore D materials

Outcome: 80D blocks show "out of range" on A durometers, leading to wrong soft parts purchase and equipment collapse.

Solution: Use Shore A (0A-98A, sharp indenter) and Shore D (30D-80D, blunt indenter) per ASTM D2240.

Pitfall 3: Testing in extreme temperatures (e.g., <0℃)

Outcome: 30A cushions tested in winter read 8A higher, causing 15% chip damage at room temperature.

Solution: Test at 23±2℃, 50±5% humidity—simulate equipment operating temperature.

Pitfall 4: Single-point testing (ignoring D-scale edge deviation)

Outcome: 20% of 80D blocks fail fitting due to 10D edge deviation from single-point tests.

Solution: 5-8 points for A-scale, 8-10 points for D-scale (avoid 2cm edges), use average value.

III. PEPSEN Full-Range Hardness Solution: Customized for Multi-Industry Needs

As a professional polyurethane component manufacturer, PEPSEN offers "Full-Range Hardness Customization" covering Shore 0A-98A-80D:

- Range-Specific Formulations:

- 0A-29A: High-elasticity polyether (90% impact absorption) for precision protection;

- 91A-98A: Wear-resistant isocyanate blend (3x better wear) for mining;

- 51D-80D: Reinforced modifier (110MPa strength) for heavy machinery.

- Precision Process Control:Low-temp curing for ultra-soft parts (no bubbles), high-temp molding for rigid parts (enhanced strength). Hardness deviation ≤±3A/±3D (vs. industry ±5A), 98% batch consistency.

- Trial Production Support:Minimum 100-unit trials, free testing to confirm suitability before mass production.

IV. Real Case Studies: Hardness Optimization Cuts Costs

Case 1: An E-Commerce Packaging Plant in Rotterdam, Netherlands (120,000 parcels processed daily)

- Pain Point: The original 50A buffer blocks for parcel sorters caused 2.5% of cartons to be crushed at corners and 1.8% of fragile items (e.g., ceramic mugs) to be damaged in packaging, resulting in €85,000 in annual compensation losses. The buffer blocks needed replacement after only 4 months due to fatigue deformation, with annual maintenance costs exceeding €60,000.

- PEPSEN Solution: Custom Shore 30A high-elasticity buffer blocks made of fatigue-resistant polyether formula, maintaining ≥94% rebound rate after 20,000 repeated compressions; rounded surface design to avoid sharp edges contacting cartons.

- Outcome: Carton crushing rate dropped to 0.3%, fragile item damage rate to 0.2%, reducing annual compensation losses by €78,000. Buffer block lifespan extended to 10 months, cutting annual maintenance costs to €22,000, with a total annual cost savings of €111,000.

Case 2: A Food Processing Plant in Munich, Germany (40 tons bread/day)

- Pain Point: 55A rollers wore 1.5mm in 3 months, failed food safety checks, regulatory warning.

- PEPSEN Solution: Shore 70A food-grade rollers (FDA 21 CFR 177.2600, wear-resistant additive).

- Outcome: 3% wear in 6 months, passed EU EC 1935/2004 inspection, 10% higher conveying efficiency.

Case 3: An Iron Mine in New South Wales, Australia (2,800 tons ore/day)

- Pain Point: Steel rollers failed monthly, 15hrs unplanned downtime ($1M lost production), overtime for maintenance.

- PEPSEN Solution: Shore 95A coated rollers (wear-resistant formula, 20mm thickness).

- Outcome: 12-month lifespan, 0 downtime, $980k saved/year, 60% lower maintenance costs.

Case 4: A Heavy Machinery Plant in Milan, Italy (180 excavators/year)

- Pain Point: Heavy steel blocks (35kg/unit) slowed assembly, 90dB noise, 20% customer complaint rate.

- PEPSEN Solution: Shore 75D polyurethane blocks (110MPa strength, mechanical structure compliant).

- Outcome: 40% weight reduction (21kg/unit), 30% faster assembly, 72dB noise, 25% higher repeat order rate.

V. Why Choose PEPSEN’s Full-Range Hardness Solutions?

- Full Range Coverage: 0A-80D, 100% fit for spill control, food, mining, heavy machinery.

- Professional Testing: A/D dual-scale testing, detailed reports to avoid "wrong hardness".

- Fast Delivery: 7-15 days for custom orders, 5-day rush service, batch shipping supported.

- After-Sales Guarantee: Free replacement + rework cost coverage for hardness/quality issues.