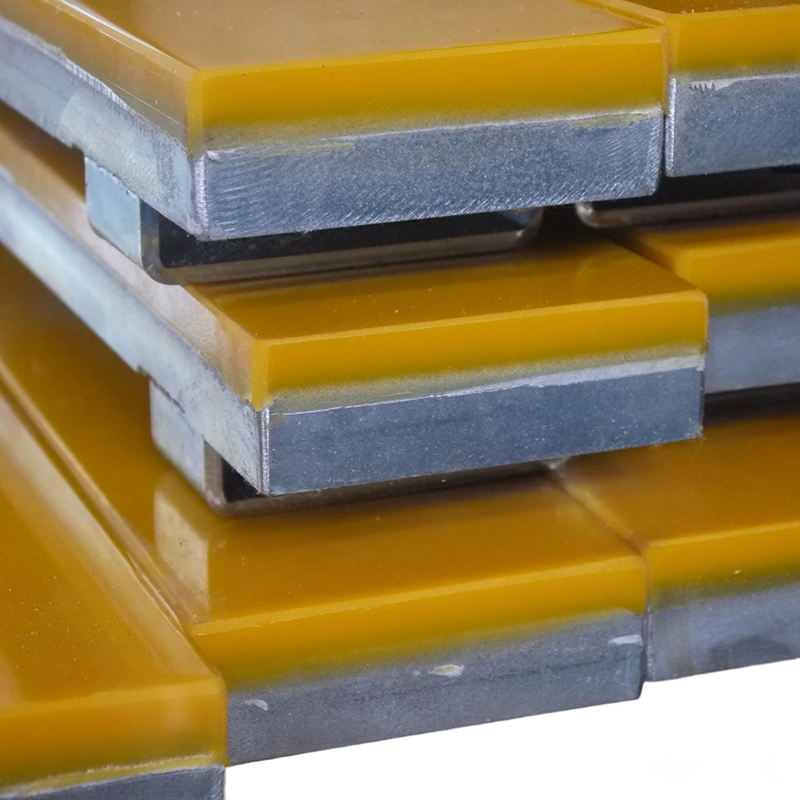

We are a China-based manufacturer and supplier of custom cast polyurethane pads, serving global industrial buyers with strict quality controls and fast lead times. Our production lines use precision molds and tested formulations to deliver pads with superior abrasion resistance, load-bearing capacity, rebound resilience, and consistent Shore A & D hardness. Competitive price structures, clear technical parameters, and on-request samples allow procurement teams to evaluate performance before committing to volume orders.

Polyurethane pads are widely used across sectors including CNC machining and tooling, conveyor systems, hydraulic presses, industrial pumps, automotive assembly lines, material handling

Customization Options:

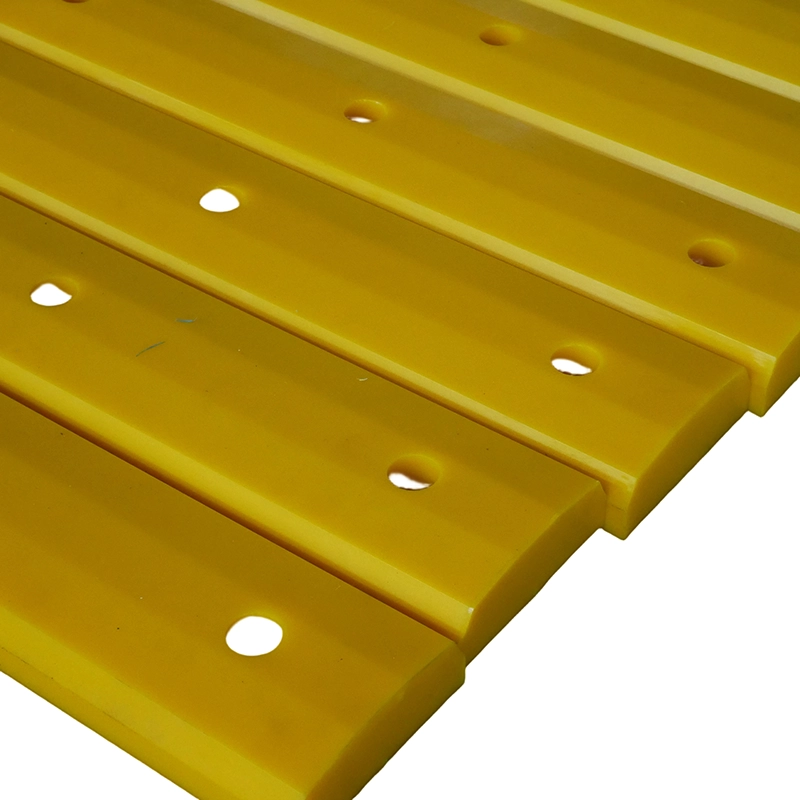

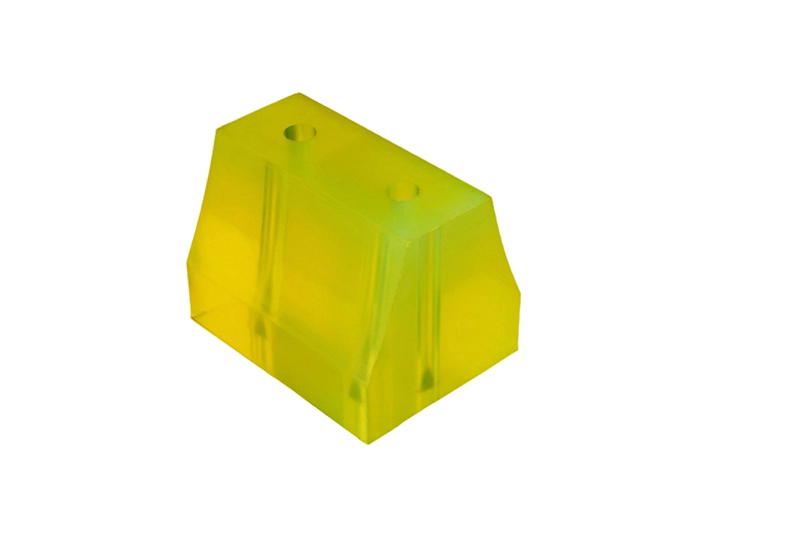

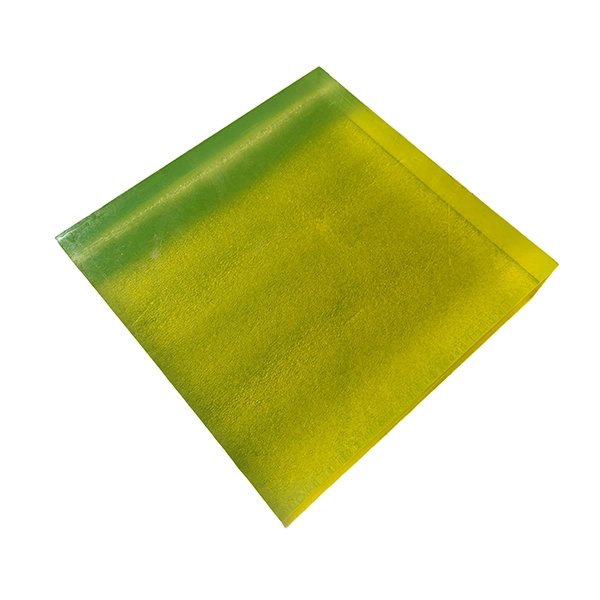

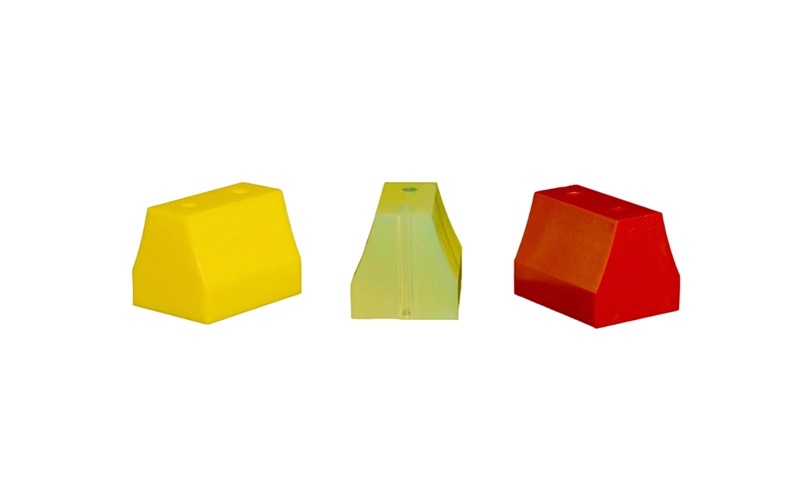

Customization Parameter Available Specifications Target Industry/Scenario Dimensions Custom diameter/length/thickness Mining crusher liners, forklift foot pads, Forklift fork pads, coil storage saddles, conveyor guide pads Hardness Shore A 40–95 (Flexible to Heavy-Duty) Vibration isolation for press machine cushions and pump mounts Shape Square, Rectangular, Circular, Custom Molds Construction machinery wear parts, automotive tooling Color Black, Yellow, Red, Custom Color-Coding Safety marking for equipment, logistics zone identification Special Features Anti-Static, UV-Stabilized, Chemical-Resistant Electronics manufacturing, outdoor mining sites, chemical plants, abrasion-heavy conveyor and stamping press Mounting Type Adhesive-Backed, Bolt-On, Interlocking Mounting on hydraulic presses and industrial motors

Applications of Polyurethane Pad

- Vibration isolation for CNC machine mounts, reducing tool chatter and improving cut quality.

- Conveyor roller support pads minimize wear and extend roller service life in material handling.

- Forklift fork pads protect loads and forks during transport and storage of coils.

- Press machine cushions absorb impact energy, protecting dies and reducing maintenance costs.

- Industrial pump mounts and compressor pads lower noise and prevent misalignment under load.

- Polishing and sanding pads provide durable, reusable surfaces for finishing applications.

- Coil storage and metal pallet supports reduce surface damage and prevent slippage.apes: make washers, spacers, vibration isolators.

Advantages of Polyurethane Pad

- Outperforms rubber pads in abrasion resistance (3x longer life in mining applications).

- Withstands extreme temperatures without brittleness (cold) or softening (heat resitance polyurethane

- Absorbs 80% of impact force, protecting equipment and reducing maintenance costs.

- Lightweight compared to metal liners, lowering machinery energy consumption.

- Chemical-resistant to oil, grease, and saltwater (ideal for marine & oil-gas sectors).

- Customizable to unique equipment shapes, eliminating ill-fit gaps and wear points.

Case Studies: How Polyurethane Pad Solved Client Challenges

- Automotive supplier improved press uptime: replacing rubber cushions with our cast polyurethane pads reduced die wear by 40% and lowered maintenance frequency.

- Metal coil warehouse reduced surface damage: custom saddle pads protected steel coils, cutting rework claims and improving product ranking among buyers.

- CNC job shop cut noise and vibration: tailored hardness pads stabilized machines, improving tolerances and reducing rejection rates.

Why Choose Our Polyurethane Pad?

- Cost advantage: 20% lower than European brands with identical performance standards.

- Outlasts rubber pads by 3x and metal liners by 1.5x in high-abrasion mining use.

- Free samples (1–3 units) with custom specs for pre-order quality verification.

- Low MOQ of 50 units, perfect for small-batch maintenance or trial projects.

- 12-month warranty, on-site technical support, and fast replacement for defects.

- Global agent partnerships available with exclusive regional distribution terms.

Selection Guide of Polyurethane Pad

- Match thickness to impact force: 5–20mm for light vibration; 50–100mm for heavy mining wear.

- Choose hardness

- Prioritize UV/chemical-resistant specs for outdoor or harsh industrial environments.

- Select mounting type: adhesive-backed for quick installs; bolt-on for permanent heavy use.

- Test custom samples to verify fit, wear resistance, and impact absorption before bulk orders.