In industrial applications, the "cheaper" material often ends up being the most expensive. While rubber has been the traditional go-to for decades, modern high-performance Polyurethane (PU) is systematically replacing it in heavy-duty environments.

If you are choosing between the two for your next batch of custom parts, you shouldn't just look at the quote price—you need to look at the downtime and replacement cycles. Here is a technical breakdown of why PU is often the superior engineering choice.

1. Extreme Abrasion Resistance

In environments involving friction—like mining, material handling, or oil & gas—rubber tends to shed particles and lose its structural integrity relatively quickly. Polyurethane, however, offers abrasion resistance that is typically 3 to 10 times higher than standard rubber compounds.

This is why we recommend PU for high-wear components like polyurethane pipe lining and slurry handling equipment. You get more "run time" before the part reaches its wear limit.

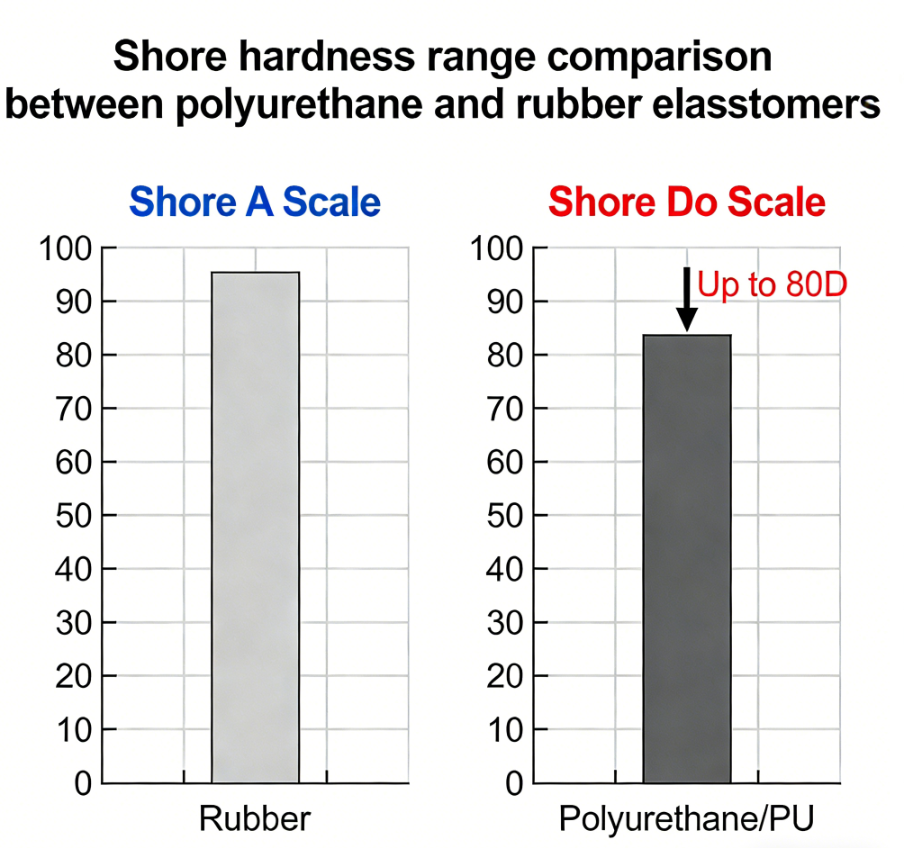

2. Load-Bearing and Shore Hardness Range

Rubber is limited. It works well in soft ranges but loses its "elastic memory" or becomes brittle when formulated to be hard. Polyurethane bridges the gap between rubber and plastic. It can be as soft as a rubber band (Shore 10A) or as hard as a bowling ball (Shore 80D), all while maintaining its elasticity.

For components like custom polyurethane bushings or heavy-load wheels, PU can support significantly higher weights without permanent deformation—a common failure point for rubber under heavy compression.

3. Environmental and Chemical Stability

One of the biggest weaknesses of natural or synthetic rubber is "dry rot" caused by ozone and UV exposure. Additionally, rubber swells and degrades rapidly when exposed to oils and fuels.

Polyurethane is naturally resistant to many industrial chemicals. Depending on the base resin used, you can tailor the part for specific environments:

- Need resistance to oils and solvents? Look at Polyester-based urethanes.

- Operating in high humidity or water? Polyether-based urethanes provide superior hydrolysis resistance, meaning they won't rot in wet conditions.

4. Heat and Temperature Performance

While rubber can handle high heat, it often hardens and cracks over time. Modern PU formulations can now withstand continuous operating temperatures that previously required expensive specialty rubbers. If your application involves thermal stress, choosing a heat-resistant polyurethane ensures the part remains flexible rather than becoming brittle and snapping.

Cost vs. Value

The initial cost of a molded polyurethane part might be higher than a generic rubber equivalent. However, the calculation changes when you factor in:

- Reduced Labor Costs: Fewer replacements mean your maintenance team spends less time fixing the same machine.

- Protection of Hardware: PU's toughness protects the expensive metal shafts or housings it is attached to.

- Customization: PU is easier and cheaper to mold into complex shapes than high-spec rubber, which requires expensive high-pressure tooling.

If your application is "set it and forget it" in a low-stress environment, rubber is fine. But if you are dealing with abrasion, heavy loads, oil exposure, or moisture, Polyurethane is the only choice that makes sense for your bottom line.

Real-World Recommendation from the Shop Floor

After casting thousands of parts, my take: for any application involving abrasion, dynamic loading, extreme temperatures, or moisture—go with polyurethane. It pays for itself in reduced downtime and replacements. We've seen clients cut annual part costs by 50%+ after switching from rubber.

If you're evaluating materials for wheels, rollers, liners, bushings, or custom molded parts, send us your specs. We'll recommend the optimal PU formulation (polyether for wet/cold, polyester for oil/high temp) and prototype quickly.

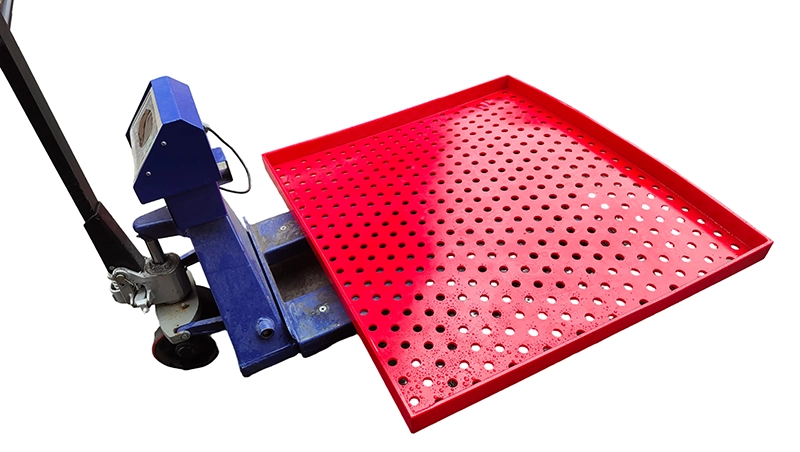

- A side-by-side photo of a used rubber roller (cracked and shedding) next to a used Pepsen PU roller (still smooth and intact).

- Real-world comparison: Rubber (left) vs. Polyurethane (right) after 500 hours of abrasive contact.

A graphic showing the Shore Hardness scale. Highlight that rubber stops around 90A, while PU extends into the D scale (hard plastic feel).

- Shore hardness range comparison between polyurethane and rubber elastomers.

- A simple check-mark table comparing PU and Rubber against "Oils," "Ozone," "Abrasion," and "Load Capacity."

- Technical breakdown: PU outperforms rubber in 4 out of 5 critical industrial categories.

"Not sure which grade is right for your application? Contact our engineering team for a customized material compatibility report."