Shanghai Pepsen Announces FDA Certification – Elevating Food-Grade Polyurethane Solutions for Global Industries

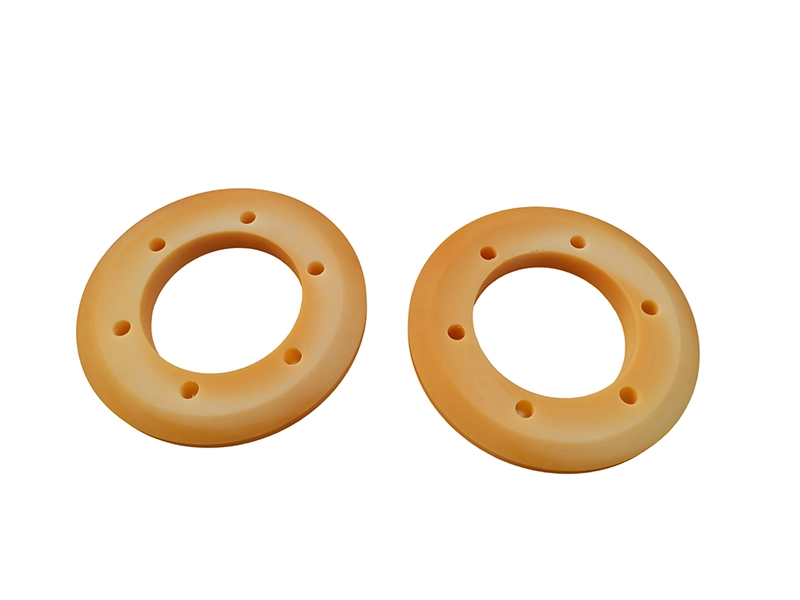

Shanghai Pepsen, a specialist in custom cast molded polyurethane products, announced it has successfully obtained FDA testing certification for its polyurethane formulations and finished parts intended for food-contact and food-adjacent industrial applications. This milestone confirms the company’s capability to supply FDA approved polyurethane wheels, rollers, seals, gaskets, and molded components that meet stringent U.S. regulatory expectations for food safety and material migration.

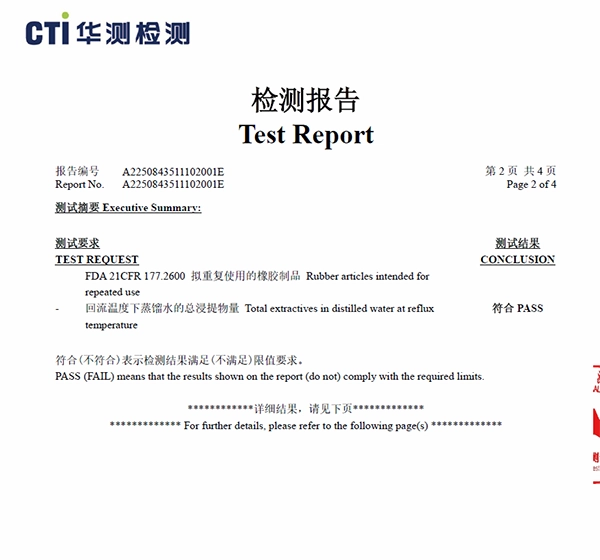

For manufacturers operating in regulated environments, the demand for reliable FDA polyurethane has never been higher. With this certification, we now offer fully compliant, custom-molded products that meet the strict standards of 21 CFR 177.1680 (for dry food contact) and 21 CFR 177.2600 (for aqueous/wet food contact) – regulations that govern the safety of materials used in producing, processing, or packaging products for human consumption . Whether you need precision-molded gaskets for food machinery or durable rollers for pharmaceutical logistics, our food-grade polyurethane combines regulatory compliance with the performance required for heavy-duty industrial use.

Below is a comprehensive guide to understanding FDA approved polyurethane, its unique advantages, industry-specific applications, and why Shanghai Pepsen’s certification indicate our goals of seeking safe, reliable polyurethane solutions.

What Is FDA Approved Polyurethane? Definition & Compliance Essentials

FDA approved polyurethane refers to cast polyurethane elastomers formulated with raw materials and manufacturing processes that meet the U.S. Food and Drug Administration (FDA)’s strict requirements for food, pharmaceutical, or medical device contact. Unlike standard polyurethane – which may contain additives, plasticizers, or impurities that pose contamination risks – food-grade polyurethane undergoes rigorous testing to ensure it does not leach harmful substances, support microbial growth, or degrade when exposed to food, beverages, or cleaning agents .

The core regulations governing FDA polyurethane are outlined in Title 21 of the Code of Federal Regulations (CFR):

- 21 CFR 177.1680: Applies to polyurethane resins used in contact with dry foods (e.g., grains, flour, sugar) that contain no free fats or oils. These materials must meet specific abrasion resistance standards, with an abrasion coefficient of at least 20 liters per mil of film thickness per ASTM method D 968-81 .

- 21 CFR 177.2600: Covers rubber articles (including polyurethane) intended for repeated contact with aqueous foods (e.g., meat, dairy, produce) or foods containing up to 8% alcohol. For aqueous food contact, total extractives must not exceed 20 mg per square inch in the first 7 hours of extraction and 1 mg per square inch in the subsequent 2 hours .

At Shanghai Pepsen, our certification goes beyond basic compliance. We test every batch for extractables, compression set, chemical resistance, and mechanical performance, ensuring our FDA polyurethane meets not just regulatory minimums but the high standards of industries where safety and durability are non-negotiable. This commitment means our customers can avoid costly recalls, maintain brand trust, and streamline operations without compromising on performance.

Industry-Specific Applications: How Our FDA Approved Polyurethane Solves Challenges

With our FDA certification, Shanghai Pepsen delivers custom food-grade polyurethane solutions for industries where safety, compliance, and durability intersect. Below are detailed applications, highlighting how our products address unique industry pain points:

1. Food Processing & Beverage

The food industry is the largest consumer of FDA polyurethane, and our certified products are trusted in applications like:

- Urethane Chute & Hopper Liners & Conveyor Guards: Our Shore 70A FDA dry-grade polyurethane liners prevent dry foods (e.g., flour, sugar) from sticking to metal surfaces, reducing waste and improving flow . A bakery customer using our liners reported a 35% decrease in product buildup and a 25% increase in line speed.

- Capper Rings & Seals: For wet food applications (e.g., dairy, meat), our 21 CFR 177.2600 compliant gaskets create a watertight seal that resists microbial growth . These seals replace rubber alternatives that absorb liquids and harbor bacteria, reducing contamination risks in bottling and packaging lines.

- Metal-Detectable Scrapers: Used in meat processing plants, our metal-detectable polyurethane scrapers remove residue from conveyor belts while ensuring any broken fragments are caught by metal detectors . This prevents costly recalls and maintains compliance with food safety standards.

2. Maritime & Cold Chain Logistics

In marine and refrigerated shipping, our FDA approved polyurethane ensures cargo safety and longevity:

- Refrigerated Container Seals: Our polyurethane gaskets provide airtight, watertight insulation for refrigerated containers, protecting perishable food or pharmaceutical cargo from temperature fluctuations and saltwater damage . Unlike rubber gaskets, they don’t crack in cold ocean temperatures (-30°C) or degrade in humid environments.

- Deck Rollers & Cargo Guides: These components guide ropes and cargo nets, reducing friction and preventing damage. Our FDA compliant rollers resist corrosion and last 3x longer than metal alternatives, lowering replacement costs for shipping companies like Maersk and CIMC .

3. Material Handling & Warehousing

For logistics and warehouses,our food-grade polyurethane improves efficiency and safety:

- Forklift Tires & Pallet Jack Wheels: Non-marking and shock-absorbent, our polyurethane tires are ideal for food and pharmaceutical warehouses. They won’t leave black rubber marks on floors and can handle loads up to 10,000 lbs without flattening. A distribution center customer reduced maintenance costs by 40% after switching from rubber tires.

- Conveyor Rollers: Our custom-molded rollers are quiet (reducing noise by 35%) and non-scratching, making them perfect for automated lines handling delicate packaging. They maintain precision even at high speeds, ensuring consistent product flow.

4. Mining & Quarrying

While mining isn’t a “food-grade” industry, our FDA approved polyurethane is used for handling food-grade minerals (e.g., salt, sugar) and avoiding contamination:

- Screen Plates: Our polyurethane screen plates separate rocks and minerals, offering 10x the lifespan of steel plates . They’re lighter (reducing equipment load) and more wear-resistant, cutting energy consumption by 25% for a customer.

- Conveyor Belt Covers: Coated with FDA compliant polyurethane, these belts transport food-grade minerals without leaching contaminants. They’re easier to clean than rubber belts, ensuring compliance with food safety standards.

5. Oil & Gas

In oil and gas, our FDA polyurethane is used for components that require chemical resistance and durability:

- Seals & Gaskets: Our polyurethane seals resist hydrocarbons and saltwater, preventing leaks in offshore drilling platforms and pipelines . They withstand high temperatures (up to 150°C) without degrading, outperforming rubber seals that fail in extreme conditions.

- Drill Bit Bushings: These components reduce friction between drill bits and casing, extending bit life by 30%. Our FDA compliant bushings are safe for use in applications where drilling fluids may come into contact with food-grade materials.

6. Automation & Mechanical Engineering

Automated lines rely on our custom FDA approved polyurethane for precision parts:

- Robot Grippers: Soft Shore 40A polyurethane grippers handle delicate components (e.g., medical syringes, food packaging) without damage. Their adjustable hardness allows them to grip both light and heavy items, improving versatility in automated systems.

- Transimission Belts: Our FDA compliant transmission belts ensure synchronized movement in food processing lines. They’re more flexible than rubber belts and won’t stretch over time, maintaining precision (error ≤±0.5%) even at high speeds .

FDA Approved Polyurethane vs. Traditional Materials: A Comparative Analysis

To understand why our FDA certification is a game-changer, let’s compare food-grade polyurethane to common alternatives across key metrics:

| Metric | Our FDA Approved Polyurethane | Rubber | Stainless Steel | Standard Plastic (PVC) |

|---|---|---|---|---|

| FDA Compliance | Meets 21 CFR 177.1680/2600; metal-detectable options | Rarely compliant; leaches chemicals | Compliant but costly for large parts | Non-compliant; toxic additives |

| Abrasion Resistance | High (2–5x longer than rubber) | Low (wears quickly in heavy use) | High but heavy/expensive | Low (cracks/scratches easily) |

| Hardness Flexibility | Shore 30A–90D (customizable) | Limited (Shore 30A–70A) | Fixed (rigid) | Fixed (brittle or soft) |

| Chemical Resistance | Resists sanitizers, oil, saltwater | Degrades in oil/sanitizers | Resists chemicals but rusts | Dissolves in strong chemicals |

| Weight | Light (1.1–1.3 g/cm³) | Heavy (1.3–1.5 g/cm³) | Very heavy (7.9 g/cm³) | Light but brittle |

| Long-Term Cost | Moderate upfront; low maintenance | Low upfront; high replacement costs | High upfront; low maintenance | Low upfront; frequent replacements |

Key Takeaways:

- vs. Rubber: Our FDA polyurethane lasts longer, resists contamination, and avoids chemical leaching. A food processor saved 60% annually by replacing rubber gaskets with our certified seals.

- vs. Stainless Steel: Our polyurethane is lighter (reducing energy use) and more flexible, making it ideal for dynamic parts like rollers. A shipping company cut fuel costs by 30% using our lightweight container seals.

- vs. Standard Plastic: Our FDA compliance eliminates contamination risks, while superior durability reduces replacement costs. A pharmaceutical company avoided a recall by switching from PVC caps to our polyurethane alternatives.

Frequently Asked Questions (FAQ) About Our FDA Approved Polyurethane

1. What’s the difference between “FDA approved polyurethane” and “food-grade polyurethane”?

They are often used interchangeably, but “FDA approved” specifically means compliance with 21 CFR 177.1680/2600. All our FDA approved products are food-grade, but not all “food-grade” materials meet FDA’s rigorous testing standards .

2. Can your FDA polyurethane be used for direct food contact?

Yes. Our formulations meet 21 CFR 177.2600 (direct contact with aqueous/wet foods) and 21 CFR 177.1680 (direct contact with dry foods).

3. Do you offer metal-detectable FDA polyurethane?

Absolutely – our metal-detectable food-grade polyurethane is engineered with additives that trigger standard metal detectors, preventing contamination in food processing lines . It’s available in custom hardness and colors (blue is most common for detectability).

4. How long does your FDA approved polyurethane last?

Lifespan depends on application, but our components typically last 1–5 years – 2–5x longer than rubber. For example, forklift tires last 2–3 years (vs. 6–12 months for rubber), and conveyor liners last 3–5 years (vs. 1–2 years for rubber) .

5. Can you custom-mold FDA polyurethane into unique shapes?

Yes – as a custom cast polyurethane manufacturer, we create parts with tight tolerances (±0.05mm) for any application. From gaskets to rollers to specialty mechanical components, we tailor our FDA polyurethane to your exact specifications .

6. Is your FDA polyurethane suitable for high-temperature applications?

Our standard formulations withstand up to 120°C, while specialized high-temperature grades handle up to 150°C – ideal for baking lines, oil and gas equipment, and industrial ovens .

7. What industries benefit most from your FDA approved polyurethane?

Food processing, beverage, maritime, material handling, mining, oil and gas, pharmaceuticals, and automation and other industries where safety, compliance, and durability are critical.