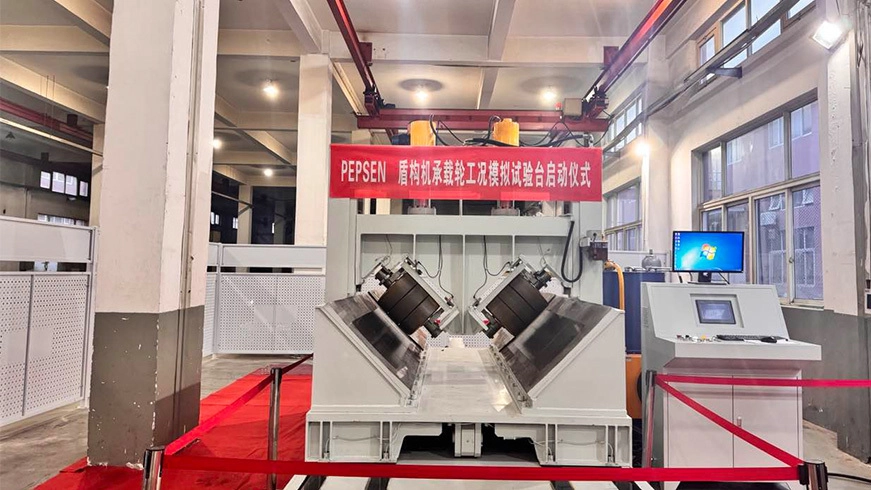

Shanghai Pepsen Launches World’s First Shield Machine Heavy Duty Polyurethane Wheels Simulation Test Bench, PEPSEN Technology Empowers National Heavy Equipment

On September 25, 2025, Shanghai PEPSEN announced a major breakthrough: its self-developed world’s first shield machine polyurethane heavy duty wheel working condition simulation test bench was officially commissioned and rolled off the production line. This pioneering achievement not only fills the global technical gap in "laboratory-based accurate simulation of real-world conditions for shield machine load-bearing wheels" but also provides core technical support to solve the long-standing industry pain point of "polyurethane wheel delamination" in underground engineering, empowering China’s "national heavy equipment" to achieve a new leap in shield machine reliability.

Industry Pain Point: Shield Machine Heavy Duty wheel Wheels Demand a Solution

As the core equipment for underground rail transit, utility tunnels, and tunnel projects, shield machines are known as "underground engineering pangolins," and their load-bearing wheels are critical components of the "walking system." During actual tunneling, polyurethane heavy duty wheels must withstand dynamic loads exceeding 30 tons per wheel, complex forces from ±15° inclined travel, underground environments with over 95% humidity, and impact friction from segment joints—conditions far harsher than ordinary industrial parts.

For years, "heavy duty wheel debonding" has been a persistent challenge limiting efficient shield machine operation: the separation between polyurethane and metal core not only causes emergency shutdowns for maintenance (costing over USD 70,000 per repair) but also delays construction schedules (each day of shutdown reduces tunnel progress by 3-5 meters) and even risks segment displacement or tunnel structural safety. Previously, the industry lacked equipment to accurately simulate real-world conditions, forcing product improvements to rely on "on-site trial and error"—a costly, time-consuming process that failed to address debonding at its root.

Core Technology: Bringing "Real-World Conditions" to the Laboratory

Bosheng’s simulation test bench, centered on "accurate reproduction and data-driven optimization," offers a new technical solution for the industry:

- Full-Scenario Condition Simulation: The test bench uses a hydraulic loading system to simulate dynamic loads of 30-50 tons per wheel, a servo motor to replicate ±15° inclined travel and segment joint impacts (0-50mm height), and adjustable humidity (50%-98%)—fully matching the complex conditions of underground tunnels;

- Real-Time Data Monitoring: Equipped with 12 sensors for pressure, temperature, displacement, and rubber layer stress, it collects 100 sets of data per second, generating real-time "heavy duty wheel tyre status" curves to visually evaluate performance of different polyurethane formulas, polyurethane thicknesses (3-15mm), and bonding processes;

- Significant Trial-and-Error Cost Reduction: Eliminating the need for on-site shield machine testing, product iteration can be completed in the laboratory, shortening R&D cycles from 6-12 months to 2-3 months and cutting trial-and-error costs by over 70%, ending the industry dilemma of "laboratory success but on-site failure."

Clear Phased Goals: PEPSEN Drives Industry Standard Upgrades

With this test bench, Shanghai Pepsen has outlined a clear roadmap to evolve from a "problem solver" to an "industry standard setter":

- Short-Term Goal (1 year): Optimize polyurethane formulas and bonding processes through over 100 sets of condition tests, reducing early failure risks (first 3 months) of load-bearing wheels by over 50% and extending service life from the current industry average of 1.5 years to 2 years;

- Mid-Term Goal (2-3 years): Completely solve the "debonding" issue, establish a mature "material-process-testing" technical system, and adapt to all models of major domestic shield machine brands (e.g., CRCHI, Shanghai Tunnel Engineering);

- Long-Term Goal (5 years): Achieve "100% reliable operation" of load-bearing wheels with a service life exceeding 3 years, reaching global leading performance, and promoting Chinese shield machine load-bearing wheel technology into international standards (e.g., ISO/TC 178) to support domestic equipment’s global expansion.

Mission-Driven: Empowering National Heavy Equipment

"Ensuring worry-free operation of China’s national heavy equipment" is the core mission of PEPSEN. The launch of this test bench is not only a milestone in the company’s technological innovation in polyurethane wheels but also reflects the responsibility of Chinese enterprises in R&D of core components for high-end equipment—breaking foreign monopolies in shield machine key component testing equipment and providing solid support for the safe and efficient advancement of national major projects such as underground engineering and rail transit.