1) Automotive (Sports Cars, Trucks, SUVs)

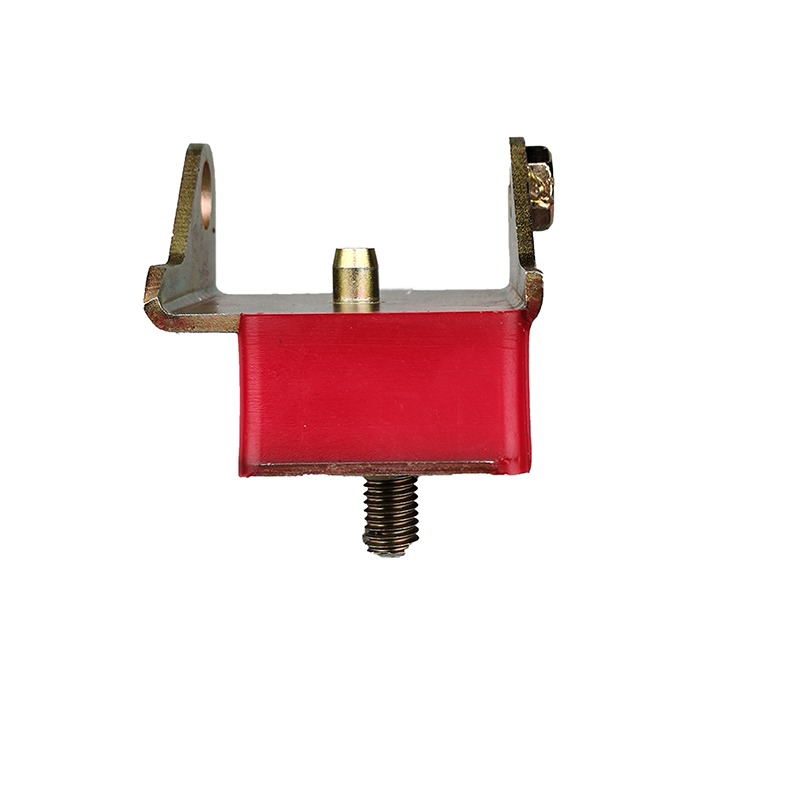

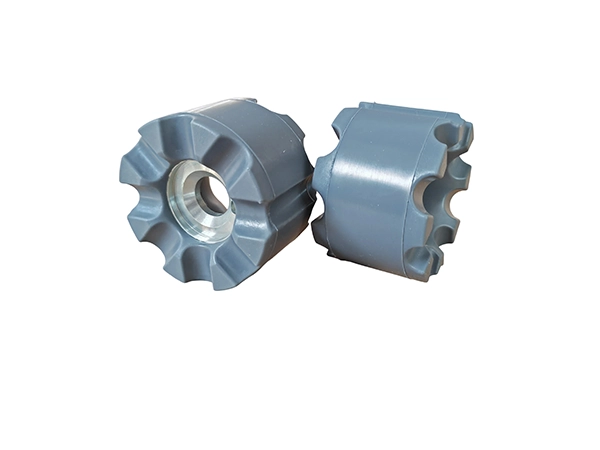

Sports cars need stable handling. Our urethane engine mounts cut vibration. They keep shifts smooth and cabin quiet.

Trucks/SUVs face heavy loads (towing, off-roading). These mounts resist wear. They last longer than rubber ones.

2) Marine (Boats & Watercraft Engines)

Saltwater and fuel harm standard mounts. Our polyurethane engine mounts fight corrosion.

Boat engines rumble nonstop. These mounts absorb vibration. They protect hulls and marine electronics.

3) Industrial (Generators, Pumps, Compressors)

Generators run 24/7. Urethane motor mounts dampen vibration. They stop machinery loosening.

Pumps/compressors work under high pressure. These mounts keep parts aligned. They extend equipment life.

4)Power Sports (ATVs, Motorcycles, Snowmobiles)

ATVs ride rough dirt trails. Our poly engine mounts absorb jolts. They keep control steady.

Motorcycles have handlebar vibration. These mounts reduce it. Rides feel smoother.

Snowmobiles face cold. These mounts avoid cracking. They work reliably all winter.