UV Resistant Polyurethane: What It Is & Why It’s Critical for Outdoor Applications

1. What Is UV Resistant Polyurethane?

UV resistant polyurethane (often called “UV-stabilized polyurethane” or “UV-protected PU”) is a specialized form of polyurethane elastomer formulated to withstand the damaging effects of ultraviolet (UV) radiation from sunlight. Unlike standard polyurethane, which degrades over time under prolonged sun exposure, leading to fading, cracking, or loss of elasticity. UV resistant variants incorporate UV inhibitors (e.g., benzotriazole, hindered amine light stabilizers) and stabilizers that absorb or neutralize UV energy before it breaks down the polymer’s molecular structure .

Two primary types dominate industrial use, aligned with our custom casting capabilities:

Extruded UV Resistant Polyurethane (TPU): Used for continuous-profile parts (e.g., conveyor belts), but less

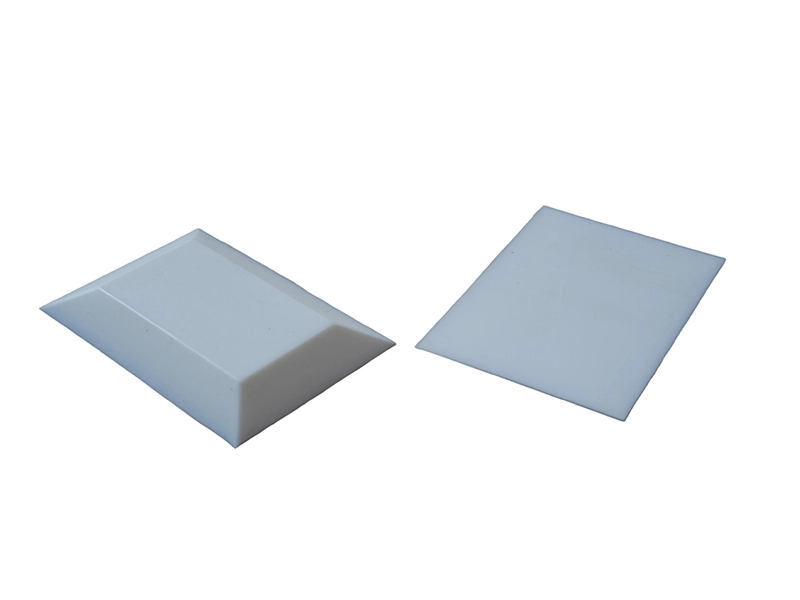

Cast UV Resistant Polyurethane (CPU): Our core product, made via low-pressure pouring into custom molds. It offers adjustable hardness (Shore A 40–Shore D 70) and can be tailored for specific outdoor stressors, from marine salt spray to mining dust.

2. Core Properties of UV Resistant Polyurethane

UV resistant polyurethane’s value lies in its ability to solve outdoor industrial pain points. These traits directly address client concerns about maintenance costs and downtime:

Retention of Mechanical Strength: Unlike epoxy or acrylic that chip off, UV resistant PU’s protection is integral to the materia, so it maintains load-bearing capacity (up to 10 tons for custom cast wheels) and impact resistance even after years of sun exposure.

Superior UV Degradation Resistance: Standard PU typically lasts 6–12 months outdoors before showing cracks; UV resistant variants extend service life to 3–5 years . Our custom cast formulations retain 80% of their elasticity after 2,000 hours of simulated sunlight.

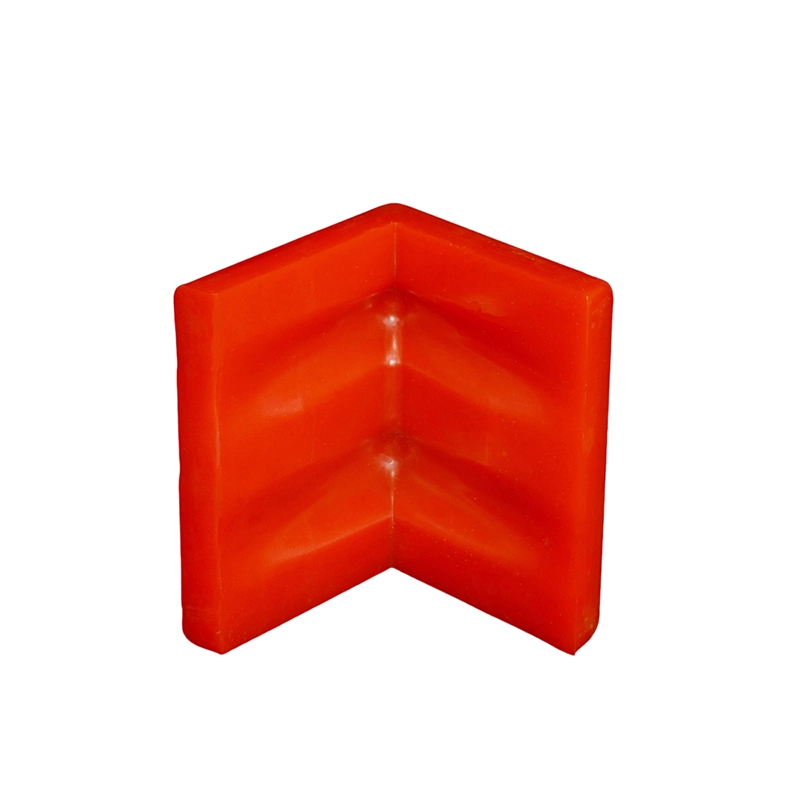

Broad Environmental Compatibility: It doesn’t just resist UV—it handles concurrent outdoor stressors: saltwater (ideal for marine), oil/grease (oil and gas), and temperature extremes (-40°C to 120°C for standard grades). A client in the North Sea reported our UV resistant PU seals outperformed rubber by 4x in saltwater+UV exposure.

Customizable Performance: Hardness, color, and additives (anti-microbial for humid mining, anti-static for automation) can be adapted. For example, we formulate 70A Shore UV resistant PU for flexible warehouse logistics rollers and 90A for rigid mining and quarrying wear parts.

3. Critical Outdoor Applications Across Industries

UV resistant polyurethane solves unique outdoor challenges in 6 high-demand sectors, with use cases tailored to our custom casting expertise:

3.1 Mining & Quarrying

Outdoor mining operations expose equipment to relentless sun, dust, and moisture. UV resistant PU thrives here:

- Conveyor Rollers & Scrapers: Our custom cast UV resistant PU conveyor belts Scrapers for iron ore and coal mines. Unlike standard rubber, they resist UV cracking and maintain grip for 3+ years (vs. 1 year for rubber), cutting replacement costs by 60%. A South African quarry reduced monthly downtime from 8 hours to 1 hour after switching.

- Chute liners and wear plates: outdoor crushing and screening plants benefit from weatherproof PU linings.

- Slurry pump components: UV and chemical exposure in tailings; UV stable grades reduce replacement frequency.

3.2 Marine (Ships & Ports)

Saltwater and UV are a destructive combination—our custom PU neutralizes both:

- Dock Bumpers & Fenders: Cast UV resistant PU bumpers absorb ship impacts while resisting sun fading and salt corrosion. European ports report these last 5 years (vs. 2 years for rubber), slashing maintenance budgets.

- Cable Protectors: UV-stabilized PU sleeves guard subsea cables from sunlight and marine growth, ensuring reliable power for offshore wind farms.

3.3 Material Handling & Warehousing

Outdoor storage yards and open-air logistics centers demand durable parts:

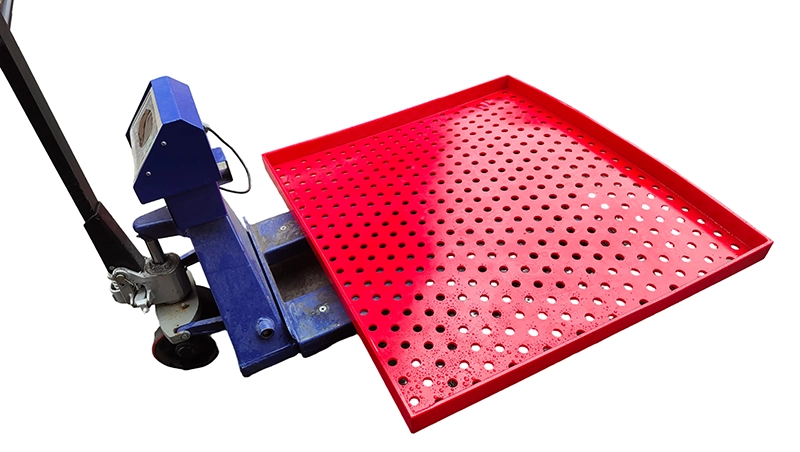

- Forklift Wheels: Our custom cast UV resistant PU wheels support 5–10 ton loads in sunny warehouses. They resist UV cracking and oil spills, lasting 3x longer than standard PU wheels. Amazon’s outdoor fulfillment centers use these to reduce replacement frequency.

- Conveyor Belt Guides: UV-stabilized PU guides keep belts aligned in outdoor sorting areas, avoiding jams caused by sun-weakened plastic guides.

- Pallet Jack Pads: Non-marking UV resistant PU pads prevent load slippage and retain grip even after years of sun exposure.

3.4 Oil & Gas

Offshore rigs and onshore pipelines face unforgiving outdoor conditions:

- Valve Seals & Gaskets: Custom cast UV resistant PU seals handle high pressure and direct sun on oil rig decks. They resist crude oil and UV, outperforming rubber seals by 3x (Caterpillar’s offshore equipment uses similar formulations).

- Pipeline Coatings: UV-stabilized PU coatings protect above-ground pipelines from sun and rain, preventing rust and reducing inspection frequency.

- Mud Pump Liners: UV resistant PU liners withstand outdoor drilling mud and sun, lasting 18 months vs. 6 months for ceramic liners.

3.5 Automotive & Road safty (Outdoor Components)

While most car parts are indoor-assembled, critical outdoor accessories rely on UV resistant PU:

- Truck Bed Liners: Custom cast UV resistant PU liners protect pickup beds from sun fading and scratches, retaining their black finish for 5+ years (vs. 2 years for non-UV liners).

- Suspension bushings and mounts: outdoor parking and road exposure demand UV resistance; PU bushings ,engine mount and transmission mount maintain elasticity and noise damping.

- Traffic polyurethane flexible bollards : outdoor parking and road exposure demand UV resistance

3.6 Power Transmission & Machinery

- Outdoor coupling elements and flexible drives: UV stable PU maintains torque transfer in uncovered equipment.

- Agricultural machinery components: tractors and harvesters operate in full sun; UV resistant PU bushings, seals, star wheels prevent premature failure.

4. UV Resistant Polyurethane vs. Competitors

To help clients make data-driven decisions, we compare UV resistant PU to common outdoor materials—highlighting gaps competitors often ignore:

| Metric | UV Resistant Polyurethane (Our CPU) | Standard Polyurethane | Rubber | Epoxy Coatings |

|---|---|---|---|---|

| Outdoor Lifespan | 3–5 years | 6–12 months | 1–2 years | 1–1.5 years (chips easily) |

| UV Resistance | Excellent (80% elasticity retained after 2,000h UV test) | Poor (cracks/fades) | Fair (fades quickly) | Good (but brittle) |

| Wear Resistance | 3–10x vs. rubber | 2–5x vs. rubber | Baseline | Low (scratches easily) |

| Customization | High (shapes, hardness, additives) | High (but no UV protection) | Limited | Very Low |

5. FAQ: UV Resistant Polyurethane for Industrial Use

Do you offer samples to test UV performance? We provide 1–5 free custom samples, with optional accelerated UV testing to validate durability in your specific climate.

What’s the lead time for custom UV resistant cast polyurethane parts? Samples: 1–2 weeks (via 3D-printed molds); bulk orders: 3–4 weeks. Expedited options are available for urgent outdoor maintenance.

Can you adjust UV protection levels for different climates? Yes—we formulate “high-UV” variants (with extra inhibitors) for tropical regions (e.g., Southeast Asia) and standard UV protection for temperate areas (e.g., Europe).

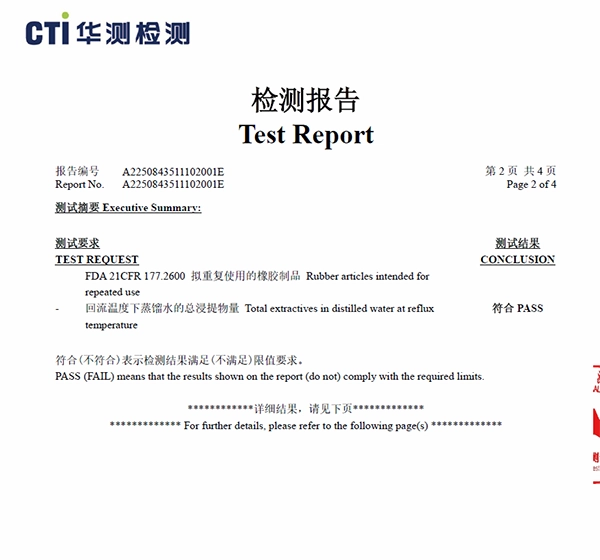

Do your UV resistant PU parts meet industry standards? All our products comply with ASTM G154 (UV exposure), REACH (EU chemical standards), and ISO 9001. For marine use, they meet IMO’s marine equipment regulations.

What’s the minimum order quantity (MOQ) for custom UV resistant PU? Our MOQ starts at 50 units which is ideal for small-scale outdoor trials (e.g., testing a new mining roller design) or maintenance needs.

Can UV resistant PU replace metal in outdoor parts? For non-structural parts (e.g., rollers, seals, bumpers), yes—it reduces weight by 50% and eliminates rust, cutting maintenance costs by 30–40%.

6. Why Choose Our Custom UV Resistant Polyurethane?

As a leading China manufacturer of custom cast UV resistant polyurethane, we align with your outdoor industrial needs:

- Tailored Protection: We not only just sell “UV resistant PU”, but also formulate it for your climate (e.g., high-salt for marine, high-dust for mining) and equipment (e.g., 85A Shore for forklift wheels, 60A for flexible seals).

- Proven Durability: Our parts are used by mining operations in Australia, ports in Germany, and logistics firms in the U.S., with 98% of clients reporting no UV-related failures in 3+ years.

- Cost Savings: Factory-direct pricing cuts 15–20% off competitor rates, and our low MOQ (50 units) lets you avoid overstocking.

- End-to-End Support: From free samples and UV testing to on-site installation guidance, we simplify your procurement process.

Selection Guide for Buyers:

- Define outdoor exposure: UV intensity, temperature range, chemical/media contact.

- Request UV aging test reports (hours, retention %, yellowing index).

- Compare lifecycle cost vs. standard and competing materials.

- Order samples for real‑environment validation.

- Evaluate supplier: test data transparency and after‑sales warranty.

[Contact Us for a Custom UV Resistant PU Quote] | [Request Free Samples]