By Jacky He | Industrial Polyurethane Specialist | 20+ Years in Custom Cast PU Elastomer Manufacturing

1. What is Cast Polyurethane (CPU)?

Cast Polyurethane (CPU) is a thermoset elastomer produced through a precision process: low-pressure mixing of degassed liquid polyurethane resin (a blend of polyols, isocyanates, and curing agents) into custom molds, followed by curing at room temperature or mild heat (100°C–120°C) . Unlike thermoplastic alternatives (e.g., TPU) that melt and re-solidify, CPU forms an irreversible cross-linked molecular structure after curing. This eliminates remolding but delivers unmatched durability and customization.

The manufacturing flexibility of CPU sets it apart: molds can be made from silicone, aluminum, or 3D-printed materials, supporting rapid prototyping and small-to-large production volumes . Whether you need a soft, rubber-like gasket (Shore A 20) or a rigid, load-bearing wheel (Shore D 70), CPU formulations can be tuned to exact specifications. This adaptability makes it a staple in industries where "one-size-fits-all" materials fail to meet performance demands.

2. Core Properties of Cast Polyurethane

CPU’s dominance in heavy industries stems from a unique combination of mechanical and chemical traits, validated by industry leaders like Covestro and BASF . These properties directly address pain points like frequent part replacement, corrosion, and downtime:

- Exceptional Wear Resistance: CPU outperforms natural rubber by 3–10x in high-abrasion scenarios (e.g., mining screens, conveyor rollers) . Its cross-linked structure resists particle erosion, extending part lifespan from months to years.

- Broad Customization: Hardness (Shore A 20–Shore D 70), color, and functional additives (anti-static, antimicrobial, flame-retardant) can be tailored. For example, oil and gas applications use chemical-resistant formulations, while electronics require anti-static blends .

- Environmental Durability: It withstands seawater, oil, solvents, and hydrolysis (moisture damage) — critical for marine and mining environments . Standard grades operate at -40°C to 120°C; custom blends reach 200°C for high-temperature industrial use. See our guide of heat resistant polyurethane.

- Cost-Efficiency: Low tooling costs ($200–$2,000 vs. $5,000+ for TPU injection molds) and long service life reduce total cost of ownership (TCO) by 35–45% compared to rubber or metal .

3. Industrial Applications of Cast Polyurethane

Cast polyurethane (CPU) has become a cornerstone material across diverse industries, thanks to its customizable performance, durability, and ability to solve sector-specific pain points. Below are expanded industrial use cases with detailed applications, performance data, and tailored solutions that address real-world challenges。

3.1 Mining & Quarrying

Mining operations demand materials that withstand abrasive ores, humid environments, and heavy loads—CPU excels in these harsh conditions:

Crusher Wear Parts: CPU jaw liners and toggle plates absorb impact from hard rock, reducing equipment vibration and extending crusher service life by 1.5x.

Scraper Blades: Antimicrobial and hydrolysis-resistant CPU blades prevent mold growth in underground mines, extending lifespan from 6 months (rubber) to 18 months. A South African gold mine reduced monthly downtime by 80% and cut maintenance costs by $42,000/year after switching to custom CPU scrapers.

Screen Panels: Dual-layer CPU screens resist tearing and clogging when processing coal, iron ore, or limestone, boosting throughput by 30% vs. steel screens. They also reduce noise by 40%, improving workplace safety.

Hydraulic Cyclone Liners: Wear-resistant CPU liners protect against slurry erosion, outlasting metal liners by 2–5x. A Brazilian iron ore mine reported a 60% reduction in liner replacement frequency.

3.2 Marine & Offshore

Seawater corrosion, salt air, and extreme pressure make marine environments hostile to most materials—CPU offers a corrosion-free, durable solution:

Cable Protectors & Grommets: Hydrolysis-resistant CPU vertebrae bend Restrictors shield electrical cables from saltwater damage, lasting 3x longer than stainless steel. Offshore wind farms use these to protect subsea cables from abrasion.

Dock Bumpers & Fender Pads: Custom-molded CPU bumpers absorb impact from ships (up to 500 tons) while resisting UV and saltwater degradation. European ports reported a 50% reduction in maintenance costs after upgrading to CPU fenders.

Propulsion System Seals: Chemical-resistant CPU seals prevent fuel and oil leakage in ship engines, complying with IMO environmental regulations .

Offshore Platform Mats: Non-slip CPU mats provide traction for workers on wet decks, reducing slip-and-fall incidents by 70%. They also resist oil, grease.

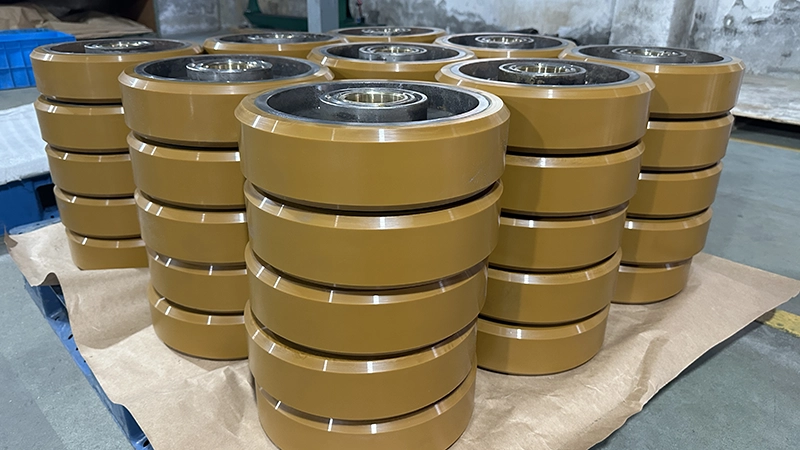

3.3 Material Handling & Warehousing

24/7 conveyor systems, heavy loads, and frequent use require parts that balance durability and flexibility—CPU delivers on both:

- Conveyor Rollers: Oil-resistant CPU rollers handle continuous operation in distribution centers, lasting 2–3 years vs. 6–12 months for rubber. Amazon’s fulfillment centers use CPU rollers to reduce downtime.

- Forklift Wheels & Casters: High-load CPU wheels (5–10 ton capacity) dampen vibration, protecting warehouse floors and reducing operator fatigue. They also have low rolling resistance, cutting energy consumption by 15%.

- Pallet Jack Pads & Grippers: Custom-shaped CPU pads improve grip on slippery or fragile loads (e.g., glass, electronics), reducing product damage by 25%.

- Conveyor Belt Scrapers: CPU scrapers remove debris and residue from belts without causing wear, extending belt life by 1.5x and reducing cleaning time by 40%.

3.4 Oil & Gas

High pressure, corrosive chemicals, and abrasive sand make oil and gas environments brutal—CPU thrives where other materials fail:

- Valve Seats & Gaskets: Bonded to metal substrates, CPU seals resist crude oil, natural gas, and sand erosion, extending valve lifespan by 3x. Caterpillar’s fracking equipment uses CPU valve seats for reliable performance.

- Drill Pipe Protectors: Wear-resistant CPU coatings prevent damage during transportation and drilling, saving mid-sized oil companies $40,000/year in replacement costs.

- Mud Pump Liners & Pistons: Chemical-resistant CPU liners handle abrasive drilling mud, outperforming ceramic liners by 18 months. They also reduce pump vibration, improving efficiency.

- Pipeline Pig Products: Ideal for oil & gas, water treatment, and chemical industries. They tackle debris, scale, and residue without damaging pipe walls. See details of pipeline pig products .

3.5 Automation & Robotics

Precision, reliability, and compatibility with delicate or heavy parts are critical in automation. CPU meets these demands:

- Robotic Gripper Pads: Custom-hardness CPU pads (Shore A 40–60) handle fragile electronics (e.g., smartphones) and heavy automotive components without damage. Tesla’s assembly lines use CPU grippers for battery module handling.

- Transmission Bushings & Bearings: Polyurethane bushings reduce noise by 30% vs. metal, improving workplace safety in automated factories. They also require no lubrication, cutting maintenance costs.

- Assembly Line Wheels: Anti-static CPU rollers prevent electrostatic discharge (ESD) in electronics manufacturing.

- Conveyor Guides & Wear Strips: Low-friction CPU guides reduce material jams on assembly lines, boosting production efficiency by 20%.

3.6 Paper & Pulp

Wet, fibrous environments degrade standard materials. CPU resists moisture, pulp buildup, and abrasion:

- Press Rollers: Smooth CPU rollers ensure uniform paper thickness while resisting pulp adhesion, reducing cleaning time by 40%. Paper mills report a 25% increase in production speed after switching to CPU rollers.

- Sludge Conveyor Scrapers: Hydrolysis-resistant CPU scrapers remove wet pulp and sludge without wearing down, lasting 12 months vs. 3 months for rubber.

- Wire Mesh Cleaners: Flexible CPU cleaners remove debris from paper machine wire meshes, extending mesh life by 1.5x and reducing downtime.

- Pulp Pump Impellers: Wear-resistant CPU impellers handle abrasive pulp slurries, outperforming metal by 2x and reducing energy consumption by 10%.

3.7 Construction & Infrastructure

Construction sites require materials that withstand heavy impact, weather, and chemical exposure. CPU delivers durability and versatility:

- Concrete Stamp: Custom-molded urethane textured stamp mat and floppy and concrete surfaces (e.g., brick, stone) without sticking, reducing formwork costs by 30%. They are reusable up to 50 times.

- Heavy Equipment Wear Parts: CPU bucket teeth, blade edges, and track pads resist abrasion from gravel and dirt, extending equipment life by 1.5x. Caterpillar uses CPU wear parts in excavators.

- Bridge Bearings & Expansion Joints: Flexible CPU bearings absorb vibration and movement in bridges, reducing structural stress. They also resist weathering and corrosion, lasting 20+ years.

- Road Marking Equipment: Polyurethane snow plow blades apply paint evenly to roads and highways, resisting solvent damage and maintaining sharp lines for 12 months vs. 6 months for rubber.

3.8 Food & Beverage Processing

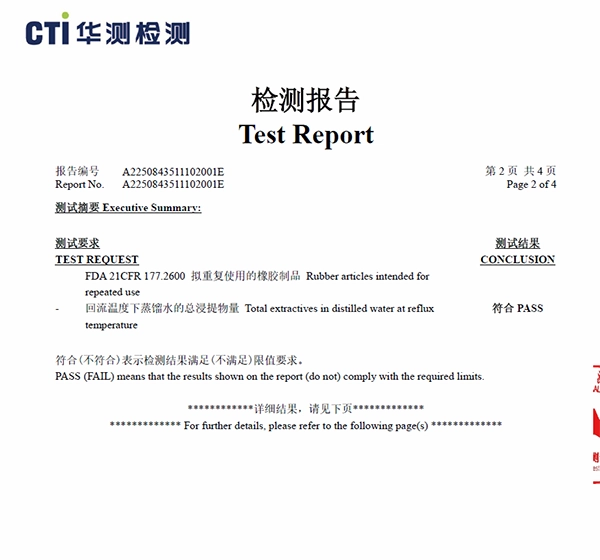

Hygiene, compliance, and durability are non-negotiable in food production. CPU meets FDA standards:

- Conveyor Belts & Rollers: FDA-compliant CPU belts resist food oils, sauces, and cleaning chemicals (e.g., bleach). They are easy to sanitize, reducing contamination risks.

- Food Cutting Boards & Scrapers: Non-porous CPU cutting boards prevent bacterial growth (e.g., Salmonella) and resist knife damage, lasting 5x longer than wooden boards.

- Filling Machine Seals & Gaskets: Chemical-resistant CPU seals prevent leaks in bottling and canning equipment, complying with FDA 21 CFR Part 177.

3.9 Agriculture & Farming

Agricultural equipment faces dirt, moisture, and heavy loads. CPU offers rugged, low-maintenance solutions:

- Tractor Tire Treads & Wheel Rims: Wear-resistant CPU treads improve traction on muddy fields, lasting 2x longer than rubber. They also reduce soil compaction.

- Harvester Wear Parts: CPU auger flights, elevator buckets, and thresher bars resist abrasion from grains and crops, extending equipment life by 1.5x.

- Irrigation System Seals & Gaskets: UV-resistant CPU seals prevent leaks in irrigation pipes and valves, withstanding outdoor weather for 5+ years.

- Livestock Equipment Components: Non-toxic CPU mats, feed trough liners, and milking machine parts resist bacteria and are easy to clean, complying with USDA standards.

4. Cast Polyurethane vs. Competitors

To help procurement teams make data-driven decisions, we compare CPU to TPU, natural rubber, and metal :

| Metric | Cast Polyurethane (CPU) | TPU (Thermoplastic PU) | Natural Rubber | Metal (Steel/Aluminum) |

|---|---|---|---|---|

| Tooling Cost | Low ($200–$2,000) | High ($5,000–$50k+) | Moderate | Very High ($10k+) |

| Lead Time | 1–3 weeks | 4–8 weeks | 2–4 weeks | 3–6 weeks |

| Wear Resistance | 3–10x vs. rubber | 2–5x vs. rubber | Baseline | High (but prone to corrosion) |

| Customization | High (shapes, additives) | Low (standard grades) | Limited | Low (machining required) |

| Corrosion Resistance | Excellent | Good | Poor | Poor (needs coatings) |

| Noise Reduction | Excellent | Good | Fair | Poor |

| Best For | Custom, low-to-medium volume | High-volume standard parts | Low-stress applications | Structural components |

5. FAQ: Cast Polyurethane for Industrial Use

How do I specify the right CPU for my application and industries? Share 3 key details: 1) Operating environment (temperature, chemicals, abrasion level); 2) Performance needs (hardness, load capacity); 3) Drawing or part dimensions. Our engineers will recommend a tailored formulation.

What’s the lead time for custom cast polyurethane parts? Samples: 2 weeks (via molds); bulk orders: 3–4 weeks. Expedited options are available for urgent maintenance needs.

What’s the minimum order quantity (MOQ) for custom CPU? Our MOQ starts at 50 units which is ideal for small-batch trials or maintenance, vs. 5,000+ units for TPU .

Can cast polyurethane replace metal parts? Yes. For non-structural parts (e.g., liners, rollers, seals). CPU reduces weight by 50% and eliminates corrosion, cutting maintenance costs by 30–40% .

Do you provide samples for testing? We offer 1–5 free custom samples to validate performance in your specific environment (e.g., seawater exposure, high-abrasion mining).

6. Why Choose Our Custom Cast Polyurethane?

As a China-based manufacturer with 20+ years of expertise, we align CPU solutions with your operational goals:

End-to-End Support: From samples and TCO analysis to on-site installation guidance, we simplify your sourcing process.

Tailored Performance: We adjust formulations for your unique environment (e.g., 85 Shore A antimicrobial CPU for humid mines, UV-stabilized blends for marine use).

Proven Reliability: Our CPU parts are used by mining operations in South Africa, ports in Europe, and automation facilities in North America with 98% positive feedback on durability.