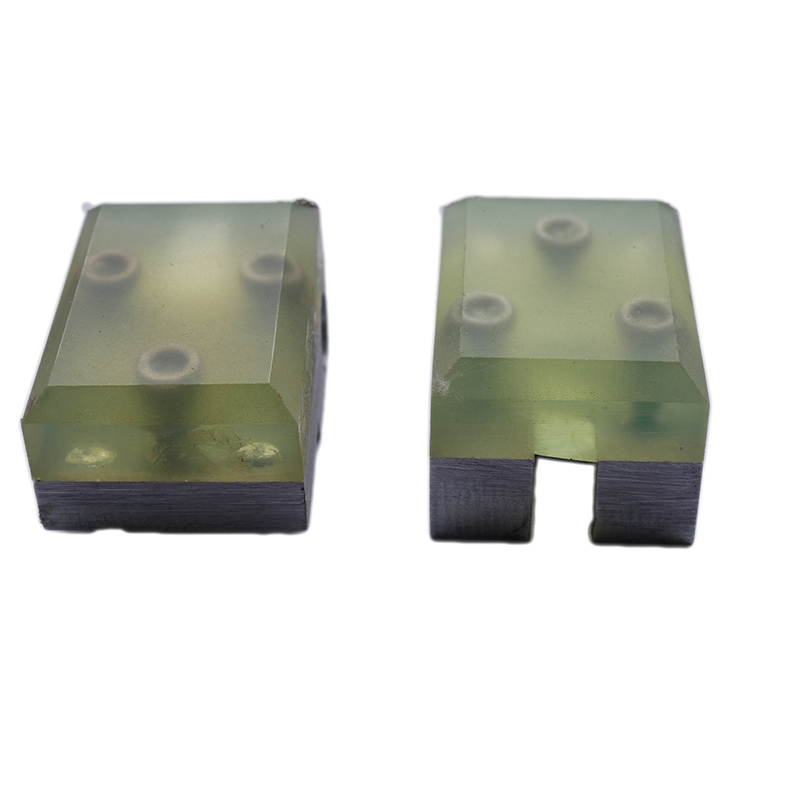

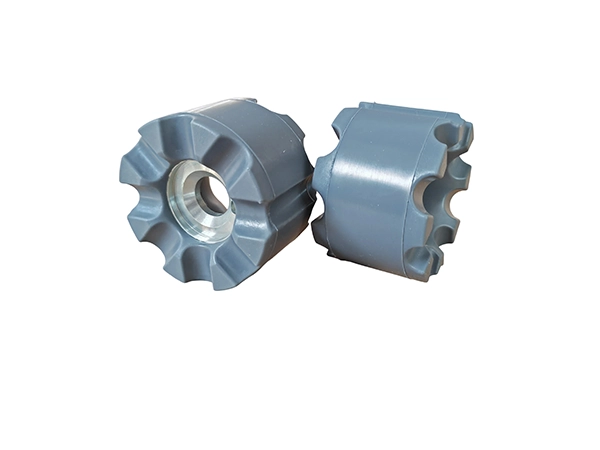

- Lower Maintenance Costs: Urethane bumpers outperform rubber counterparts with better abrasion/tear (5 times) and impact resistance. Longer lifespan improves process efficiency by reducing frequent part replacements.

- Weather and UV resistance: It won’t crack or harden when exposed to ozone/oxygen , suitable for outdoor application.

- Chemical Resistance: Our urethane bumpers resist more chemicals than most rubbers/plastics, suiting oil refineries, food/beverage plants, and paper/pulp facilities.

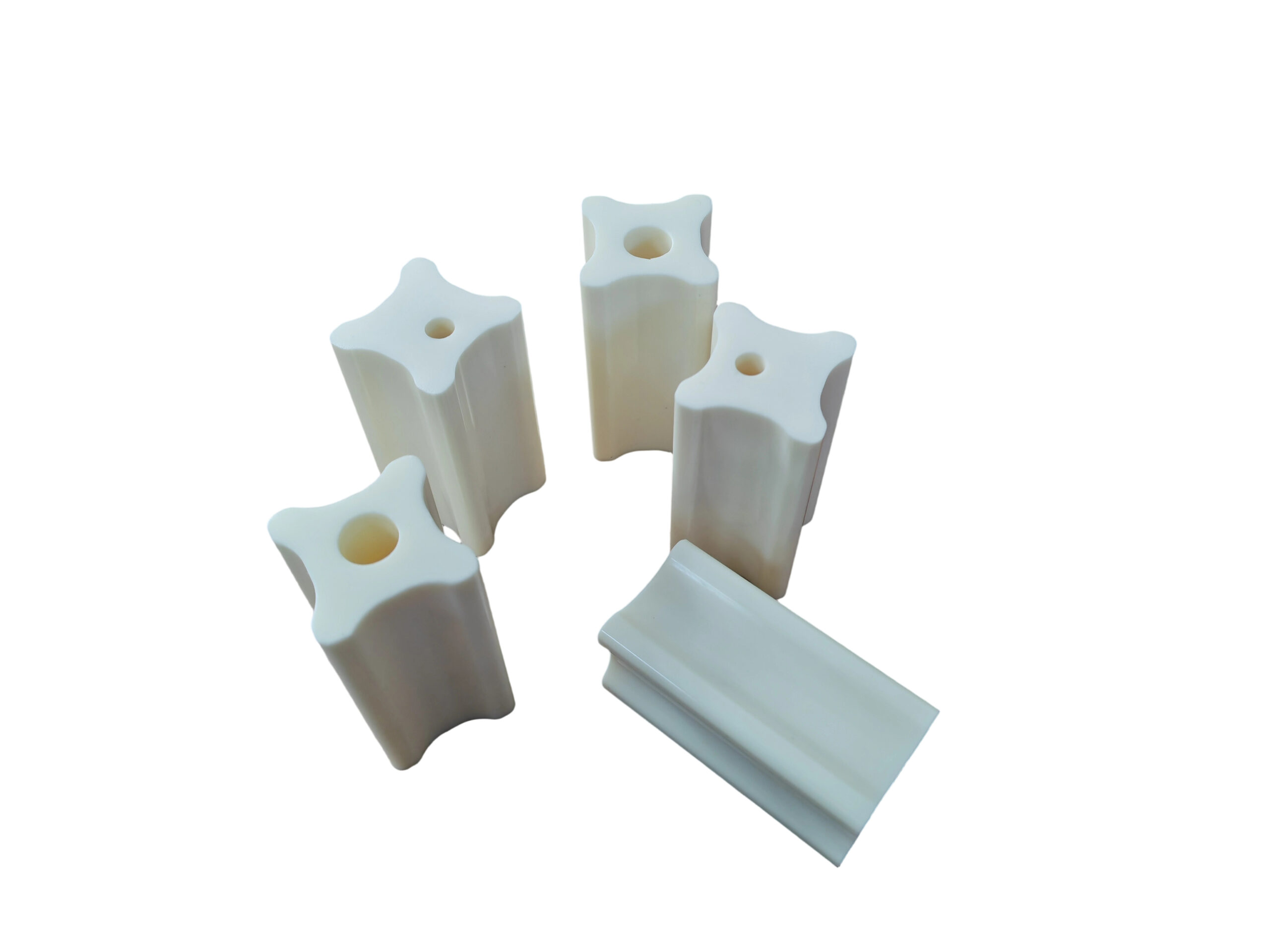

- Non-marking: Urethane bumpers are non-marking, bondable to metal/wood/plastics, and FDA-compliant .

- Lower Tooling Costs: Urethane has lower tooling costs than rubber/plastics, making it economical for prototypes and low-volume bumper production.

- Noise Dampening & Vibration Dampening: Urethane bumpers reduce noise, vibration, and movement transfer especially in heavy machinery. They creat safer, quieter workspaces .

- Guiding and Alignment: Bumpers guide and align components in automated and manufacturing systems.