Custom Cast Polyurethane Parts That Work Harder: Wheels, Rollers, Bushings & More from PEPSEN

At PEPSEN, we’ve focused on one thing since 2004: making polyurethane parts that outlast the alternatives in real industrial duty. If you’re an OEM, maintenance manager, or distributor dealing with frequent wear, noise, or premature failures, you already know the pattern—rubber tears or swells, nylon cracks or flat-spots, steel corrodes or damages mating surfaces.

That’s exactly where custom cast polyurethane changes the game. With the right formulation and hardness, a urethane part can deliver 2–5× longer service life, reduce downtime, and bring consistency back to your operation.

Here’s how we design our core product families—and what you should look for when upgrading or replacing your wear parts.

Why PEPSEN uses cast polyurethane (not “one-grade fits all”)

Polyurethane isn’t a single material. It’s a tunable elastomer system. In our casting process, we can tailor:

- Hardness from soft, high-grip elastomers to near-rigid wear grades

- Polyether or polyester systems based on water, oil, slurry, or dry abrasion

- Additives for anti-static, non-marking, UV resistance, heat resistance, and more

- Geometry for grooves, flanges, crowns, and multi-durometer builds

- Strong urethane-to-metal bonding for high-torque or high-load parts

If you want the full range of what we produce, start at our Polyurethane Products hub.

1) Polyurethane Wheels: stop chunking, improve traction, carry more load

Our polyurethane wheels are built for the places where rolling parts take impact + abrasion + static loading all at once—warehouses, mines, crushers, conveyors, construction equipment, and automated lines.

Typical wheel styles we cast

- Heavy-duty load wheels (forklifts, carriers, AGVs)

- Drive / idler / guide wheels

- Flanged wheels for rail tracking

- V-groove and U-groove wheels for conveyors/automation

- No-crush wheels for delicate panels and bottling lines

What we solve most often

- Tread chunking on rubble floors

- Permanent set after overnight static loads

- Oil softening/swelling

- Edge tearing from side loads

For delicate handling or shock-prone duty, our no-crush wheels and rollers are a common upgrade path.

What to share for a fast quote

- Wheel OD/width/profile

- Load per wheel + duty cycle

- Speed + rolling surface condition

- Environment (oil/water/fines/heat)

- Core/bearing details or an existing sample

2) Polyurethane Rollers: longer wear life without losing precision

Rollers are everywhere—pipe handling, belt conveyors, packaging lines, high-speed automation, and wet process lines. We cast polyurethane rollers to deliver a tough wear surface while keeping stable geometry under load.

Typical rollers we supply

- Urethane-coated rollers bonded to steel cores

- Grooved/crowned rollers for tracking

- High-abrasion conveyor rollers

- Wet-environment rollers for corrosion-prone lines

- Drive rollers for heavy-duty torque transfer

Common failures we replace

- Grooving from abrasive fines

- Rust pitting and surface scoring

- Diameter drift from plastic creep

- Slippage or tracking issues

When a metal core is still good, we can re-cast urethane onto it using our urethane-to-metal bonding process—often saving both time and cost.

What to share for a fast quote

- Roller OD/length + shaft drawings

- Coating thickness requirement

- Load/pressure + operating speed

- Media exposure (slurry/oil/water/chemicals)

- Surface finish/texture + tracking needs

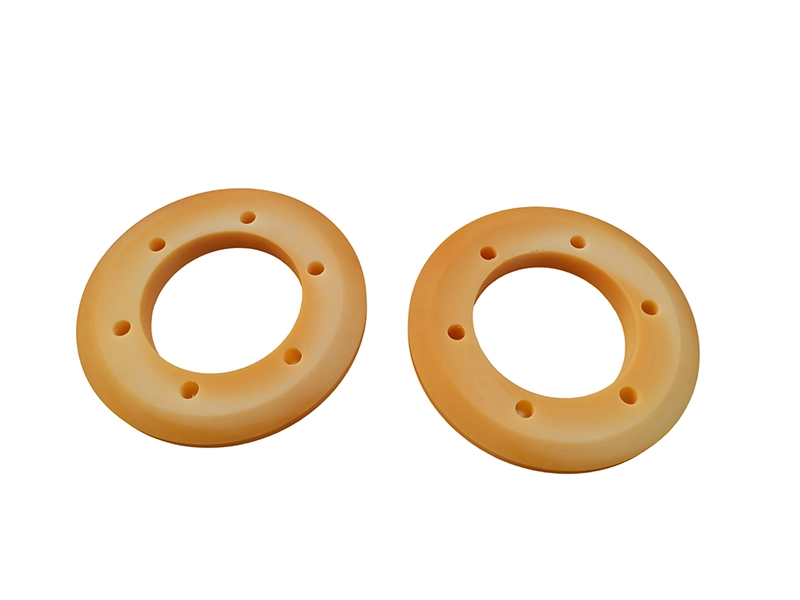

3) Polyurethane Bushings: resist oil, control deflection, last longer than rubber

In suspension, pivots, dampers, and industrial linkages, rubber bushings tend to fail by tearing, swelling, or excessive deformation. Our cast polyurethane bushings are designed to carry heavier loads with predictable deflection and far better wear life.

Where customers see the biggest gains

- Automotive/off-road suspension & NVH parts

- Industrial pivot points and vibration isolation

- Oil-exposed machinery and workshop environments

- OEM assemblies requiring press-fit precision

What to share for a fast quote

- ID/OD/length + sleeve details

- Working load + deflection window

- Temperature + oil/chemical exposure

- Failure mode of current part

- Drawing, 3D file, or physical sample

Beyond the big three: full custom casting for harsh industries

Many buyers start with wheels/rollers/bushings, then expand into other PU wear and sealing products. Our custom molded polyurethane parts include everything from specialty spacers to reinforced wear components.

Two common examples:

- Oil & gas / pipeline maintenance:

Our pipeline pig products are cast for aggressive cleaning, batching, and separation duty, with sizes and hardness tuned to your pipe condition. - Mining & conveying wear protection:

We cast polyurethane linings and blades to reduce gouging, noise, and replacement frequency in hoppers, chutes, and transfer points.

Send an RFQ that gets you the right material on the first try

To recommend the best formulation quickly, we only need a few essentials:

- Drawing / 3D file / physical sample

- Application + equipment type

- Load per part + duty cycle

- Speed / rolling contact condition

- Temperature range

- Exposure media (oil, water, slurry, solvents, UV)

- Current part failure mode

- Your target improvement (life, grip, noise, fit, etc.)

Ready for a quote or material recommendation?

If you want a like-for-like replacement—or a performance upgrade—send your drawing/sample and working conditions. Our engineers will recommend the right polyurethane system and provide pricing with clear lead times.

Contact PEPSEN here — we reply within 24 hours.