1) Suspension Systems

Polyurethane bushings outperform rubber in suspension parts such as control arms, sway bars, linkages. They improve vehicle stability, handling, and lifespan.

2) Motor Mounts

They isolate engine vibrations and shocks for a smoother ride, cutting wear on connected vehicle components.

3) Heavy-Duty Vehicles

Critical for trucks, trailers, forklifts: absorb shocks, reduce noise, and boost durability in tough logistics settings.

4) Specialty Vehicles

Used for high-performance, motorsport, and custom car to support heavy loads and deliver superior control.

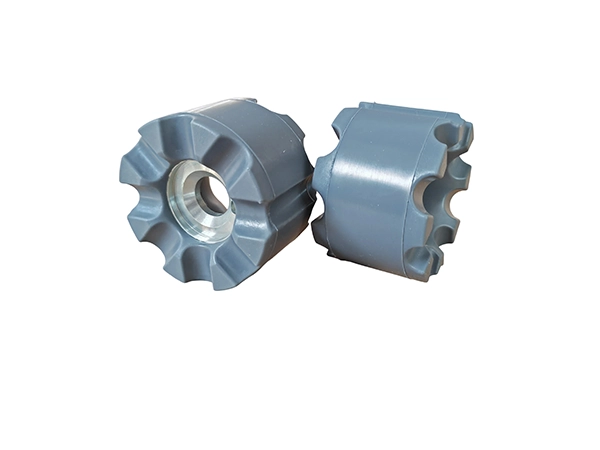

5) Industrial Machinery & Equipment

Pivots & Load Points: Support lift system pivots and machinery load-bearing joints, preventing wear for reliable use.

Material Handling: Used on conveyors to absorb impact and protect products as they move.

Specialized Equipment: Fit cranes and industrial machines which need strong, custom-molded solutions for vibration isolation and alignment.

6) Protective Components

Serve as impact pads, bumpers, or mounting pads to prevent fragile parts/equipment from damaging.