When engineers and purchasing specialists evaluate materials for tough industrial environments, poliuretano moldeado often stands out for its unique combination of mechanical durability and resistance to chemicals, oils, and solvents. Whether in minería machinery, logistics automation, or heavy equipment hydraulics, knowing when and why to specify chemical, oil, and solvent resistant cast polyurethane can radically improve performance and reduce maintenance costs.

This guide breaks down what cast polyurethane is, how its chemical and oil resistance works, applications across industries, how it compares to competing materials, and answers common engineering questions. All are written with practical insights engineers and procurement teams actually care about.

Understanding Cast Polyurethane: Definition and What Sets It Apart

Cast polyurethane is a thermoset elastomer produced by mixing liquid polyols and isocyanates and pouring the reactive blend into a mold where it cures into the final product. Unlike thermoplastics or standard rubbers, cast PU undergoes a chemical cross-linking reaction during cure that produces a resilient and durable elastomer tailored for specific industrial demands.

Cast PU’s versatility comes from customizable formulations that can be tuned for hardness (e.g., from Shore A 5 to Shore D 80 levels), tear strength, abrasion resistance, and critically, chemical/Oil resistance. This flexibility makes cast polyurethane suitable for components that face continuous contact with hydrocarbons, lubricants, water, and mild solvents—situations where traditional rubbers or plastics may fail prematurely.

Importantly, cast PU does not swell significantly in many petroleum-based oils or hydraulic fluids, and it maintains dimensional stability under load. That’s why design manuals and material resistance charts often list cast polyurethane as a strong choice for components like seals, bushings, rollers, and liners in chemical-exposed environments.

However, engineers should be aware that not all chemicals are equal. While cast polyurethane displays excellent resistance to mineral oils, petroleum products, and many aliphatic solvents, it can show weakness against strong acids, ketones, and pure aromatics unless specially formulated grades are used. Material selection should always consider the specific chemicals, concentrations, and operating temperatures encountered in service.

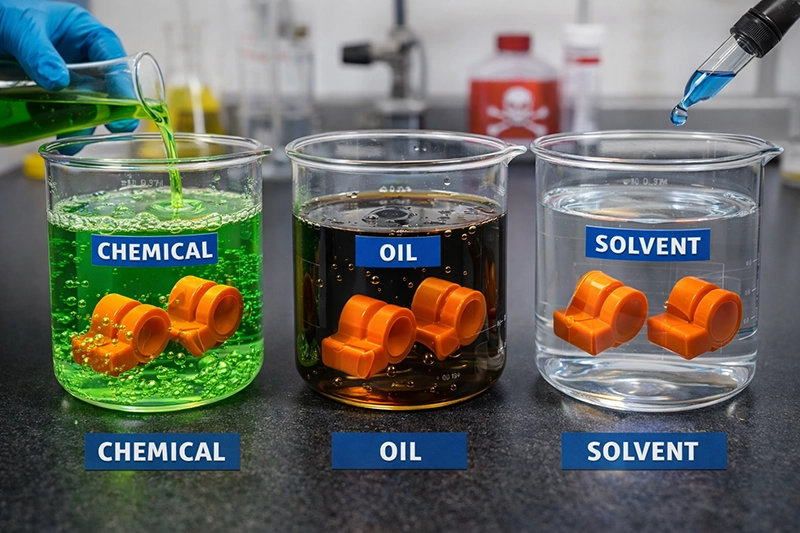

Chemical, Oil & Solvent Resistance Characteristics

When specifying cast polyurethane for environments involving chemicals or hydrocarbons, it helps to understand how its molecular structure contributes to its resistance profile:

Chemical Resistance Fundamentals

Cast polyurethane’s chemical resistance depends on its molecular makeup (polyester vs. polyether bases), cross-link density, and hard/soft segment balance. Higher cross-link density typically improves resistance to oils and non-polar solvents. Polyester-based PU generally resists grease and petroleum products better than polyether variants, though polyether types often perform better in hydrolysis resistance.

Oil & Hydrocarbon Resistance

PU elastomers excel in environments with mineral oils, petroleum hydrocarbons, and common hydraulic fluids. These fluids are generally non-reactive with the polymer chain, so PU doesn’t undergo rapid softening or cracking—one reason cast polyurethane wheels, seals, and hose liners last longer than rubber in oily industrial settings.

Solvent Exposure

Short-term exposure to mild solvents like alcohols and ethers is usually tolerable for cast polyurethane, but prolonged contact with strong solvents (e.g., acetone, benzene, strong ketones) can degrade elastomeric properties. Always consult supplier resistance charts and conduct field tests with actual working fluids before committing to material selection.

Temperature Sensitivity and Chemical Interaction

Temperature often amplifies chemical effects—higher operating temperatures can accelerate chemical attack or soften elastomers. PU compounds designed for higher thermal resistance should be evaluated with anticipated fluid temperatures in mind.

In summary, cast polyurethane’s resistance profile makes it a high-value option for components that contact oils and many industrial solvents, but careful assessment is key when dealing with aggressive chemicals or extreme temperatures.

Cast Polyurethane Resistance Applications: Warehouse Logistics, Mining Quarry, Construction Machinery

Cast polyurethane’s chemical, oil, and solvent resistance is not an abstract property. It drives real performance benefits across a range of demanding industries. Below are detailed use cases where CPU elastomers stand out:

1. Warehouse Automation & Material Handling

In modern warehouses and logistics centers, reliability and uptime are key. Cast polyurethane parts such as:

- Load-bearing wheels and rollers on automated guided vehicles (AGVs)

- Conveyor rollers exposed to cleaning agents and lubricants

- Bumpers and dock seals subject to fuel and hydraulic fluid exposure

need to withstand regular contact with hydraulic oils, petroleum greases, and cleaning solvents. Cast PU’s resistance to these media, combined with excellent abrasion performance, reduces unscheduled maintenance and part replacement compared to natural rubber or standard plastics.

2. Mining, Aggregates & Heavy Mining Machinery

Mining environments present both heavy mechanical stress and exposure to oils, grease, and slurry liquids. Typical cast PU parts include:

- Liners for crushers and screens where abrasive rock and lubricants co-exist

- Slurry pump housings and impeller liners that confront chemical lubricants mixed with abrasive media

- Belt scrapers and chute liners in systems frequently cleaned with solvent-based fluids

In all these cases, polyurethane’s ability to resist oil film build-up and maintain performance under abrasive, chemically contaminated conditions sets it apart from standard elastomers and thermoplastics.

3. Construction & Mobile Hydraulic Equipment

Construction machines like excavators, cranes, and compactors rely on high-performance components that survive oil exposure and harsh environments. Cast PU is often used for:

- Hydraulic seals and piston boots resistant to oil and heat

- Shock pads and vibration dampers that encounter grease and solvent cleaners

- Track pads and wear liners on equipment exposed to oil spill points

Because cast polyurethane handles the dual stress of mechanical loads and oil environments better than many competitors, equipment stays operational longer between service intervals.

4. Automotive & Heavy Vehicle Components

Though less obvious than rubber parts in consumer cars, cast polyurethane appears in heavy vehicles and off-road equipment for:

- Bushings and vibration mounts that confront engine oils and transmission fluids

- Seal rings and gaskets in hydraulic assemblies

- Custom rollers and guides for production lines where solvents and oils are used in cleaning and maintenance

Across these scenarios, cast PU helps reduce downtime, minimizes wear in chemical environments, and delivers consistent performance under fluctuating loads.

Cast Polyurethane vs. Competitive Materials

Choosing the right material often means comparing cast polyurethane with alternatives like natural rubber, thermoplastic elastomers (TPE/TPU), and metal parts.

Caucho natural

Natural rubber can handle elasticity and impact well, but it fails quicker than CPU when exposed to mineral oils, petroleum products, and many solvents. It tends to swell, lose resilience, and crack under chemical exposure which makes it less suitable for oil-rich environments than cast PU.

Thermoplastic Urethane (TPU)

TPU offers good flexibility and resistance to abrasion, but in prolonged chemical or oil exposure it may soften more quickly than thermoset cast polyurethane. TPU is ideal for lighter load or non-critical contact with oils, but cast PU’s durability often outperforms TPU in industrial uses.

Metals

Metals like steel or aluminum resist many chemicals well, but they don’t offer the vibration damping, impact resilience, and noise reduction that elastomers bring to applications like rollers, seals, and bushings. Cast PU often provides a superior balance of mechanical and chemical performance, especially where interaction with oils and solvents is frequent.

Overall, cast polyurethane’s unique combination of mechanical properties and chemical/oil resistance often makes it the material of choice in industrial environments where durability and uptime matter most.

Quick Comparison Table

| Material | Oil Resistance (1,000 Hours) | Chemical Resistance (Weak Acids/Alkalis) | Solvent Resistance (Hydrocarbons) | Flexibility | Wear Life (Industrial Settings) |

|---|---|---|---|---|---|

| Custom Cast Polyurethane | ≤3% Volume Change | Excellent (Resists Hydrolysis) | Excelente | Alto | 12+ Months |

| Rubber (Nitrile) | 35-40% Volume Change | Poor (Swells/Softens) | Poor (Degrades Quickly) | Alto | 3-6 Weeks |

| Nylon | 15-20% Volume Change | Bien | Fair (Warping) | Low | 6-8 Months |

| Metal (Steel) | Good (Prone to Rust) | Excelente | Excelente | Low | 12+ Months (High Maintenance) |

FAQ: Cast Polyurethane Chemical, Oil, And Solvent Resistance

Q1: Is cast polyurethane resistant to all chemicals?

Not all. Cast polyurethane offers excellent resistance to many mineral oils, petroleum products, and mild solvents, but can deteriorate with strong acids, ketones, and pure aromatic solvents unless specialized formulations are selected. Always consult resistance charts and test in real conditions.

Q2: How do I choose the right PU grade for oil resistance?

Consider the type of chemical, temperature range, and exposure duration. Polyester-based PU tends to resist oils better, and higher hardness grades often improve resistance to non-polar fluids.

Q3: Can cast polyurethane be used in hydraulic components?

Yes, many seals, boots, and elastomeric parts in hydraulic systems are cast from polyurethane because of its resistance to hydraulic fluids and mechanical stresses. Proper formulation and testing are key.

Q4: How does temperature affect chemical resistance?

Higher temperatures often increase chemical diffusion and soften elastomers. Choose formulations rated for the expected thermal range and consider heat aging effects in design.

Q5: Is custom cast polyurethane more expensive than other materials?

Upfront costs can be higher than simple rubber or basic plastics, but longer service life, lower maintenance, and reduced downtime often result in lower total cost of ownership.

Q6: What’s the difference between polyether & polyester PU for chemical/oil resistance?Polyether cast PU excels in chemical/water-rich environments (warehouse logistics, slurry mining) and resists hydrolysis; polyester cast PU offers superior oil resistance (construction machinery, dry quarrying). We’ll help you choose based on your exact fluid exposure—just share your media list.