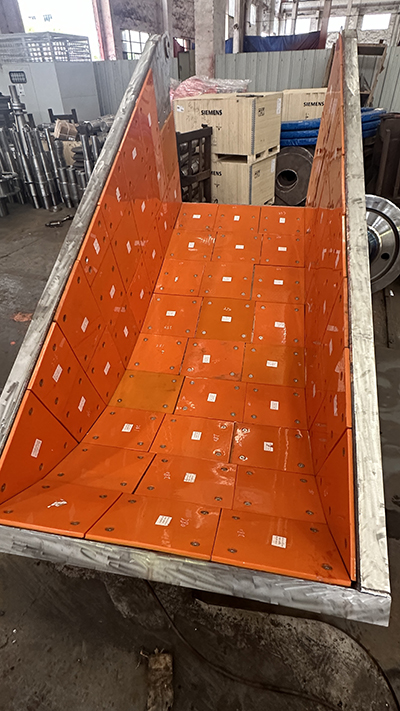

Urethane Liners/Lining for Industrial Equipment Protection

- Superior abrasion resistance extends chute and hopper lifespan by 300%+ compared to steel.

- Custom cast urethane liners fit any equipment size for seamless installation.

- Chemical and impact-resistant urethane liners reduce maintenance downtime.

- Reduces equipment noise by 20-30% through vibration dampening

- Resists oils, chemicals, and UV damage for long-term durability

- Plyurethane lining offers strong hydrolysis resistance for wet conditions.

- Manufacturing for customized hardness, color and shape

INDUSTRIES SERVED: Mining, Construction, Wastewater, Food Processing