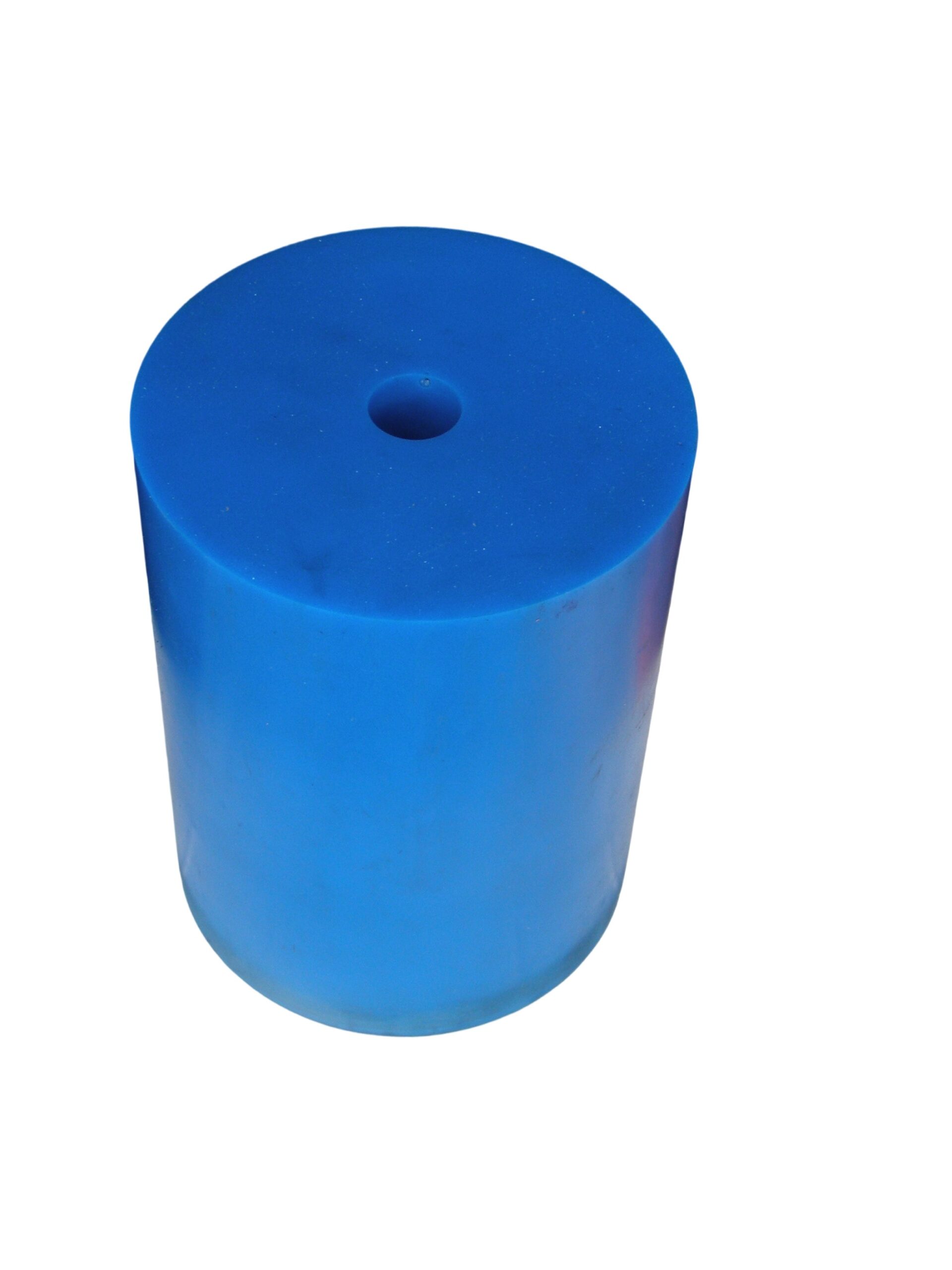

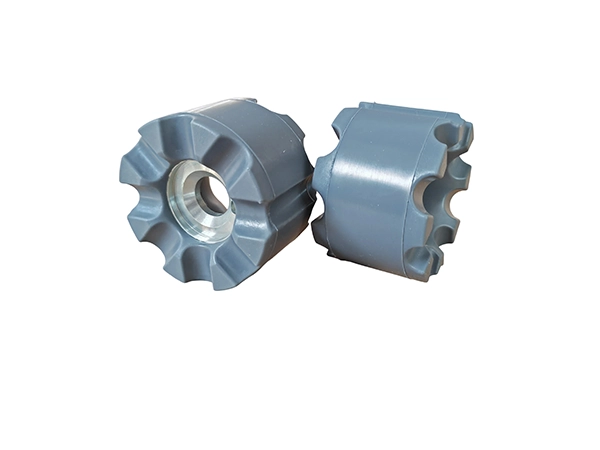

- Automotive : They are widely used in punching, stamping and drawing dies manufacturing; . They are also used as automotive bushings to enhance comfort .

- Industrial & Manufacturing: Use as key components for die-casting, stamping, and punching operations, compression performance ensures long service life. they are also applied in shock absorbers and various vibration-dampening scenarios .

- Transportation & Elevators: Counting on reliable performance and the capacity to withstand continuous mechanical stress, urethane springs are suitable for locomotive suspensions, elevators, and escalators, guaranteeing the safe operation of these high-frequency-use devices.

- Furniture & Bedding: Used in furniture, mattresses, and beds, they not only disperse pressure and boost comfort but also provide durable, body-conforming support to improve product user experience.

- Construction: Integrated into buildings and bridges, they absorb vibrations from external sources like earthquakes and wind, effectively enhancing the structures’ earthquake resistance.

- Agriculture: Applied to heavy machinery and equipment in the agricultural sector, they serve as durable, shock-absorbing components to protect equipment and ensure smooth farming operations.