Polyurethane washers, with benifits like wear resistance, chemical resistance, and shock absorption, are widely used in various industries.

Household Products: In kitchen and bathroom fixtures , polyurethane washers provide reliable sealing performance to prevent water leakage. Their food-grade formulation, water resistance and chemical resistance also enable long-term use and safty in humid environments.

Automotive Industry: Used in engine components, suspension systems, and transmission devices to provide shock absorption, cushioning, and sealing. For instance, at the connection between an automobile engine’s intake and exhaust manifolds, polyurethane washers can effectively prevent gas leakage while absorbing vibrations and impacts generated during engine operation, extending the service life of components.

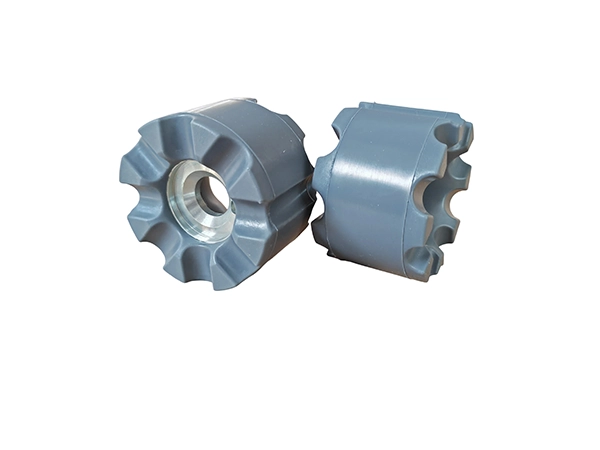

Industrial Manufacturing: Applied at connection points of mechanical equipment (e.g., gears, bearings, bolts), polyurethane washers offer excellent sealing and cushioning performance. They block dust, oil, and moisture from entering, reducing component wear and malfunctions. Additionally, in scenarios like conveyor belt scrapers and pipeline cleaning, their wear resistance and cut resistance effectively enhance equipment operational efficiency and stability.

Oil and Gas Industry: During oil and gas extraction, transportation, and processing, polyurethane washers are used in pipeline connections and valve sealing. With good oil resistance and corrosion resistance, they can withstand high pressure and harsh working environments.