- Logistics and Warehousing Industry

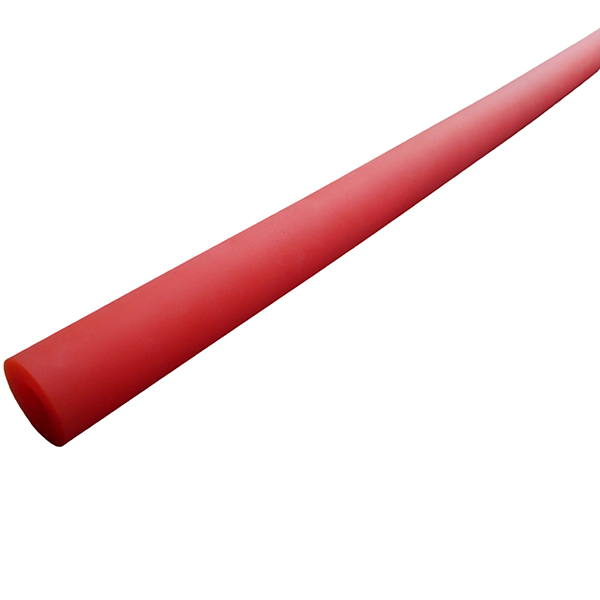

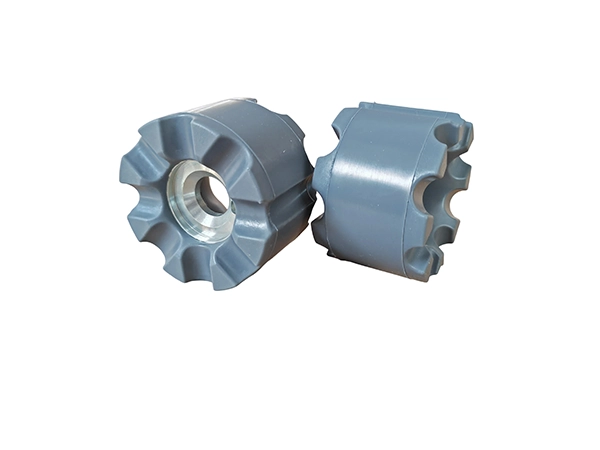

E-commerce Sorting Line Gravity Rollers: Sleeved on gravity-driven roller surfaces to enhance wear resistance and reduce damage to express parcels .

Warehouse Conveyor Rollers: Reduce friction noise between rollers and cartons/pallets, suitable for high-frequency cargo turnover scenarios.

- Light Industry Manufacturing Industry

Textile/Plastic Film /Glass Production Lines: provide high surface smoothness to avoid wrinkling or scratching of fabrics/films .

-Printing Machine Paper Guide Rollers: Adapt to different hardness requirements (60A–98A) to ensure stable paper conveyance without deviation.

- Mining/Heavy Industry Auxiliary Scenarios

Light Conveyor Rollers in Mineral Processing Plants: Resist wear from ore dust, reducing the frequency of frequent roller replacements.

Silo Transition Rollers: Cushion the impact of falling ore/granular materials to protect roller substrates from impact deformation.

- Food Cold Chain Industry

Fresh Produce/Bakery Conveyor Lines: Adopt FDA-certified food-grade polyurethane to avoid food contamination, withstanding a temperature range of -30℃ to 120℃.

Freezing Tunnel Conveyor Rollers: Feature strong cushioning to prevent frozen foods from breaking.