소개

In industrial environments where extreme temperatures, heavy loads, and harsh chemicals converge, material performance can make or break operational efficiency. Heat resistant polyurethane (also known as heat resistant urethane or heat resistant PU) has emerged as an excellent elastomer, bridging the gap between the flexibility of rubber, the durability of metal, and the versatility of plastic. As a leading China-based manufacturer specializing in custom cast 폴리우레탄 제품, we’ve witnessed firsthand how this advanced material transforms industries ranging from oil and gas to marine shipping and automated manufacturing.

This comprehensive guide will unpack everything you need to know about heat resistant polyurethane from its scientific definition and key properties to applications, competitive advantages. Whether you’re seeking to replace failure-prone rubber components in high-heat machinery or source reliable materials for extreme-temperature logistics, this article will help you understand why heat resistant PU has become the material of choice for forward-thinking industries worldwide.

What is Heat Resistant Polyurethane?

Heat resistant polyurethane is a specialized elastomer engineered through a precise reaction between isocyanates and polyols, modified with advanced additives to withstand elevated temperatures without sacrificing performance . Unlike standard polyurethane, which typically struggles at continuous temperatures above 80°C, heat resistant urethane formulations are designed to maintain structural integrity and mechanical properties in environments ranging from -30°C to 120°C, with high-performance grades enduring short-term exposure to 150°C .

At its core, the heat resistance of this material stems from its molecular structure. Manufacturers adjust crosslink density and incorporate polycarbonate-based polyols or specialized chain extenders (such as BDO or HQEE) to enhance thermal stability . This customization allows heat resistant PU to resist thermal degradation, hydrolysis, and oxidation—common pitfalls of conventional elastomers in high-heat settings. As a custom cast product, it can be tailored to specific temperature ranges, hardness levels (from Shore 10A to 95A), and physical properties, making it adaptable to diverse industrial needs .

Crucially, heat resistant polyurethane retains the signature benefits of standard PU such as elasticity, abrasion resistance, and load-bearing capacity, while adding thermal resilience. This unique combination means it doesn’t just survive high temperatures; it performs reliably, reducing downtime and replacement costs for critical applications. Whether cast into rollers, gaskets, wear plates, or custom components, heat resistant urethane delivers consistency where other materials fail.

Key Properties of Heat Resistant Polyurethane (Heat Resistant Urethane)

The widespread adoption of heat resistant PU across industries is rooted in its exceptional, balanced properties, especially when exposed to extreme temperatures. Below are the core characteristics that make it indispensable for high-heat applications:

1. Superior Thermal Stability

The defining feature of heat resistant polyurethane is its ability to maintain performance across a broad temperature spectrum. Unlike rubber, which softens and degrades above 80°C, or plastics that become brittle or melt, heat resistant urethane retains elasticity and structural integrity at continuous operating temperatures up to 120°C .

2. Exceptional Wear & Tear Resistance

Heat resistant polyurethane outperforms rubber, plastic, and even some metals in abrasion resistance . In high-heat industrial settings where friction, impact, and mechanical stress are constant, this property translates to longer component lifespans. For example, heat resistant PU rollers in conveyor systems endure repeated contact with heavy loads without wearing thin, while seals maintain their shape despite constant thermal expansion and contraction.

3. Chemical & Environmental Resistance

High-temperature environments often involve exposure to oils, solvents, greases, and corrosive substances which heat resistant urethane handles easily . It resists hydrolysis (degradation from moisture) and chemical attack, making it ideal for applications like oil and gas drilling or marine shipping, where exposure to harsh fluids and humidity is unavoidable. Unlike traditional materials which release harmful particles when degraded, heat resistant PU is a safe, non-toxic alternative .

4. High Load-Bearing Capacity

Heat resistant polyurethane offers a higher load-bearing capacity than conventional rubber, even at elevated temperatures . This means it can support heavy machinery, cargo, or industrial components without permanent deformation. For instance, heat resistant PU wear plates in mining equipment withstand tons of rock and ore while maintaining their thickness and performance, reducing maintenance frequency.

5. Customizability & Versatility

As a custom cast elastomer, heat resistant polyurethane can be tailored to specific application needs. Manufacturers can adjust hardness (from soft, rubber-like 70A to super rigid 80D), density, and shape to fit unique components, ranging from tiny seals to large conveyor rollers . It also integrates seamlessly with other materials, such as steel cores for rollers or metal substrates for wear plates, enhancing durability and functionality.

6. Noise Reduction & Vibration Dampening

In high-heat machinery, noise and vibration are common byproducts of operation. Heat resistant urethane’s elastic properties absorb shock and dampen vibrations, creating quieter, smoother-running equipment. This is particularly valuable in automated manufacturing lines , logistics & warehouse facilities, where noise reduction improves workplace safety and efficiency.

Industry Applications of Heat Resistant Polyurethane (Heat Resistant PU)

Heat resistant polyurethane’s unique blend of thermal stability, durability, and customizability makes it a versatile solution across diverse industries, especially those facing high temperatures, heavy loads, and harsh conditions. Below are detailed applications in key sectors, highlighting how custom cast heat resistant urethane components solve real-world challenges:

1. Oil & Gas Industry

The oil and gas sector operates in some of the most extreme thermal environments—from downhole drilling (where temperatures exceed 100°C) to refinery pipelines and processing equipment. Heat resistant polyurethane components are critical here:

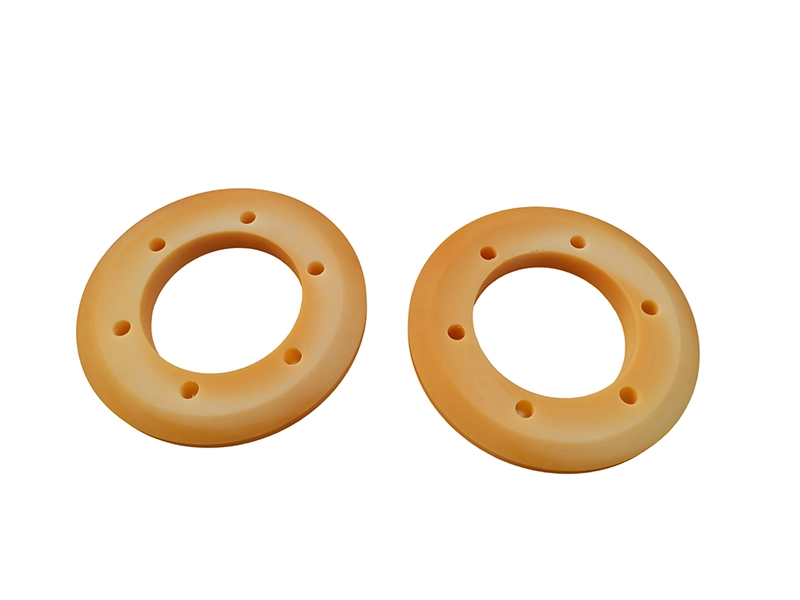

- Drill Bits & Seals: Heat resistant PU seals and gaskets in drilling equipment withstand high temperatures and exposure to oil, gas, and drilling fluids, preventing leaks and ensuring operational safety.

- Pipeline Lining & Wear Pads: Custom cast heat resistant PU linings protect pipelines from corrosion and abrasion, even in desert or offshore environments with extreme temperature swings.

- Valve Components: Heat resistant urethane valve seats and O-rings maintain sealing integrity at high pressures and temperatures, reducing downtime in refineries and processing plants.

2. Mining & Quarrying

Mining and quarrying involve heavy machinery, constant friction, and exposure to dust, moisture, and high temperatures from equipment operation. Heat resistant PU excels in this sector:

- Wear Plates & Liners: Heat resistant polyurethane liners in crushers, screens, and chutes reduce abrasion from rocks and ore, extending equipment life by 3-5x compared to metal or rubber .

- Conveyor Rollers & Idlers: Custom cast heat resistant PU rollers endure the heat generated by continuous operation and heavy loads, preventing belt slippage and reducing maintenance.

- Drill Rod Protectors: Heat resistant PU sleeves protect drill rods from wear and thermal damage during deep mining operations, where temperatures rise with depth.

3. Marine (Shipping) Industry

Marine environments present a double challenge: high temperatures (from engine rooms and tropical climates) and moisture/humidity. Heat resistant polyurethane components thrive here:

- Engine Seals & Gaskets: Heat resistant PU seals in ship engines withstand temperatures up to 120°C, preventing water and oil leaks in harsh marine conditions.

- Cargo Handling Rollers: Heat resistant urethane rollers on ship decks and loading docks handle heavy containers while resisting UV radiation, saltwater corrosion, and temperature fluctuations.

- Hull Protectors: Custom cast heat resistant PU fenders and hull protectors absorb impact from docks and other vessels, maintaining flexibility even in extreme heat or cold.

4. Automation & Manufacturing

Automated production lines, especially in automotive, electronics, and packaging industries, generate heat from continuous operation. Heat resistant PU ensures smooth, reliable performance:

- Conveyor Belts & Rollers: Heat resistant polyurethane rollers in automated conveyors withstand the heat from motors and friction, ensuring consistent movement of products (e.g., car parts, electronics) through high-temperature processing zones.

- Robotic Grippers & Pads: Custom heat resistant PU grippers maintain elasticity and grip strength in automated assembly lines, even when exposed to heat from welding or curing processes.

- Mold Inserts & Components: Heat resistant urethane mold inserts in injection molding machines resist high temperatures, improving mold life and product quality.

5. Warehousing & Material Handling

Warehouses and distribution centers rely on conveyor systems, lifts, and storage equipment that operate continuously—generating heat from friction and motor use. Heat resistant PU components deliver value here:

- Pallet Jack Wheels & Casters: Heat resistant polyurethane wheels on pallet jacks and forklifts withstand the heat of frequent use on warehouse floors, offering better traction and durability than rubber wheels.

- Conveyor Belt Scrapers: Heat resistant PU scrapers remove debris from conveyor belts without damaging the belt, even in high-temperature storage facilities (e.g., food processing warehouses).

- Storage Rack Protectors: Custom cast heat resistant urethane guards protect racking from impacts, maintaining structural integrity in hot or cold storage zones.

6. Paper & Pulp Industry

Paper mills operate with high-temperature boilers, drying machines, and processing equipment—creating harsh conditions for materials. Heat resistant PU components are essential:

- Roll Covers & Sleeves: Heat resistant polyurethane roll covers on paper drying machines withstand temperatures up to 120°C, ensuring uniform paper thickness and reducing roll wear.

- Seals & Gaskets: Heat resistant urethane seals in boiler systems and pulp processing equipment prevent steam and chemical leaks, even in high-humidity, high-heat environments.

- Wear Strips & Guides: Heat resistant PU wear strips guide paper through processing machines, resisting abrasion and heat without damaging the paper.

7. Power Transmission & Mechanical Engineering

Mechanical systems—such as gears, bearings, and transmission components—generate heat during operation. Heat resistant polyurethane enhances reliability:

Custom Mechanical Components: Cast-to-order heat resistant PU parts (e.g., sprockets, couplings) fit unique mechanical designs, offering thermal stability and durability where standard components fail.

Gear Teeth & Bushings: Heat resistant PU gear teeth and bushings reduce friction and noise, maintaining performance at high temperatures without lubrication issues.

Torsion Bushings & Dampers: Heat resistant urethane dampers absorb vibration in engines and transmission systems, protecting components from thermal and mechanical stress.

Heat Resistant Polyurethane vs. Competitor Materials

To understand why heat resistant PU is the preferred choice for high-temperature applications, it’s critical to compare it to traditional and alternative materials. Below is a detailed breakdown of how heat resistant polyurethane (heat resistant urethane) outperforms rubber, plastic, metal, and other elastomers:

1. Heat Resistant PU vs. Rubber

Rubber is a common elastomer, but it falls short in high-heat environments:

- Thermal Stability: Rubber softens above 80°C and degrades rapidly at 100°C, while heat resistant polyurethane operates reliably up to 120°C .

- 내마모성: Heat resistant PU is 3-5x more abrasion-resistant than rubber, extending component life in high-friction, high-heat settings .

- 내화학성: Rubber swells or degrades when exposed to oils, solvents, or chemicals—common in high-heat industrial environments—while heat resistant urethane resists these substances .

- 부하 용량: Heat resistant polyurethane supports heavier loads without deformation, making it ideal for heavy machinery in high-temperature zones.

2. Heat Resistant PU vs. Plastic

Plastics like nylon or polyethylene are cost-effective but lack thermal and mechanical resilience:

- Temperature Tolerance: Most plastics become brittle below 0°C or melt above 100°C, while heat resistant PU maintains flexibility from -40°C to 120°C .

- Impact Resistance: Heat resistant urethane absorbs impacts without cracking, even at high temperatures—unlike plastics, which shatter or deform under stress .

- Elastic Memory: Plastics retain permanent deformation after stress, while heat resistant PU returns to its original shape—critical for seals, gaskets, and dynamic components.

3. Heat Resistant PU vs. Metal

Metals (steel, aluminum) are durable but have significant drawbacks in high-heat applications:

- Weight & Noise: Heat resistant polyurethane is lighter than metal, reducing equipment weight and energy consumption. It also dampens noise and vibration, unlike metal, which amplifies them .

- Corrosion Resistance: Metals rust or corrode in high-heat, high-humidity environments (e.g., marine, oil and gas), while heat resistant PU is corrosion-proof .

- Cost-Effectiveness: Metal components are expensive to manufacture and replace. Heat resistant PU has a lower total cost of ownership due to longer lifespans and reduced maintenance .

4. Heat Resistant PU vs. Standard Polyurethane

Standard PU is versatile but not designed for high temperatures:

- Thermal Limits: Standard polyurethane degrades above 80°C, while heat resistant PU is modified to withstand 120°C+ with minimal performance loss .

- 가수분해 저항: Heat resistant urethane resists moisture-induced degradation (hydrolysis) in high-heat, humid environments—an issue that exceeds standard PU .

- Long-Term Stability: Heat resistant PU maintains properties over years of high-temperature use, while standard PU hardens, cracks, or loses elasticity.

5. Heat Resistant PU vs. Asbestos

Asbestos was once used for high-heat applications but is now obsolete due to safety risks:

- Safety: Asbestos releases toxic fibers when degraded, while heat resistant polyurethane is non-toxic and safe for industrial use .

- Performance: Heat resistant PU offers better flexibility, chemical resistance, and durability than asbestos, with no health hazards.

In summary, heat resistant polyurethane combines the best properties of competing materials—thermal stability, durability, flexibility, and chemical resistance—while eliminating their flaws. For high-temperature industrial applications, it delivers unmatched value in terms of performance, safety, and cost-effectiveness.

FAQ About Heat Resistant Polyurethane (Heat Resistant Urethane/PU)

Below are answers to the most common questions we receive about heat resistant polyurethane, based on customer inquiries and industry trends:

1. What is the maximum temperature heat resistant polyurethane can withstand?

Most standard heat resistant PU formulations operate continuously at 120°C, with high-performance grades enduring short-term exposure to 150°C .

2. Can heat resistant urethane be customized for specific applications?

Yes—As a custom cast elastomer manufacturer, we tailor heat resistant PU to your needs: adjust hardness (70A-95A), shape, size, and thermal resistance to match your equipment’s requirements . Whether you need small seals or large conveyor rollers, custom formulations ensure perfect fit and performance.

3. How long does heat resistant PU last in high-temperature environments?

Heat resistant polyurethane components typically last 3-5x longer than rubber or plastic alternatives . In industrial settings (e.g., mining conveyors, oil refineries), expect a service life of 2-5 years with regular use.

4. Is heat resistant polyurethane resistant to chemicals and moisture?

Absolutely. Heat resistant urethane resists oils, solvents, greases, and hydrolysis (moisture-induced degradation) . This makes it ideal for marine, oil and gas, and chemical processing applications where exposure to harsh fluids is common.

5. Can heat resistant PU replace metal components?

Yes. In many cases. Heat resistant polyurethane is lighter, quieter, and more corrosion-resistant than metal, while offering comparable load-bearing capacity . It’s commonly used to replace metal wear plates, bushings, and rollers, reducing equipment weight and maintenance costs.

6. What industries benefit most from heat resistant polyurethane?

Industries with high-temperature, high-stress environments gain the most: oil and gas, mining, marine shipping, automation, warehousing, paper and pulp, and power transmission . Any application where rubber, plastic, or metal components fail due to heat or wear will benefit from heat resistant PU.

7. How does heat resistant polyurethane compare to standard polyurethane in cost?

Heat resistant PU has a higher cost than standard PU, but its longer lifespan and lower maintenance needs result in a lower total cost of ownership . For high-heat applications, the investment pays off in reduced downtime and replacement expenses.

8. Can heat resistant urethane be used in food-grade applications?

Yes, food-grade heat resistant PU formulations are available, meeting FDA standards for contact with food products. These are ideal for food processing facilities with high-temperature equipment (e.g., baking, drying lines).

결론

Heat resistant polyurethane (heat resistant urethane/heat resistant PU) has established itself as a critical material for modern industry, offering unmatched thermal stability, durability, and versatility in high-temperature environments. From oil and gas drilling to marine shipping, automation, and mining, it solves the pain points of traditional materials—extending component lifespans, reducing downtime, and lowering total costs.

As a China-based manufacturer specializing in custom cast molded polyurethane products, we’re committed to delivering heat resistant PU solutions tailored to your unique needs. Whether you require a custom gasket for a high-temperature valve, wear plates for mining equipment, or rollers for automated conveyors, our heat resistant urethane components combine scientific innovation with practical performance.

The future of heat resistant polyurethane is bright—with advances in formulation, sustainability, and smart technology expanding its potential across industries. By choosing heat resistant PU, you’re not just investing in a material; you’re investing in reliability, efficiency, and long-term success for your operations.

If you have questions about how heat resistant polyurethane can enhance your products or processes, contact our team today. We’ll work with you to develop a custom solution that meets your temperature requirements, performance goals, and budget.