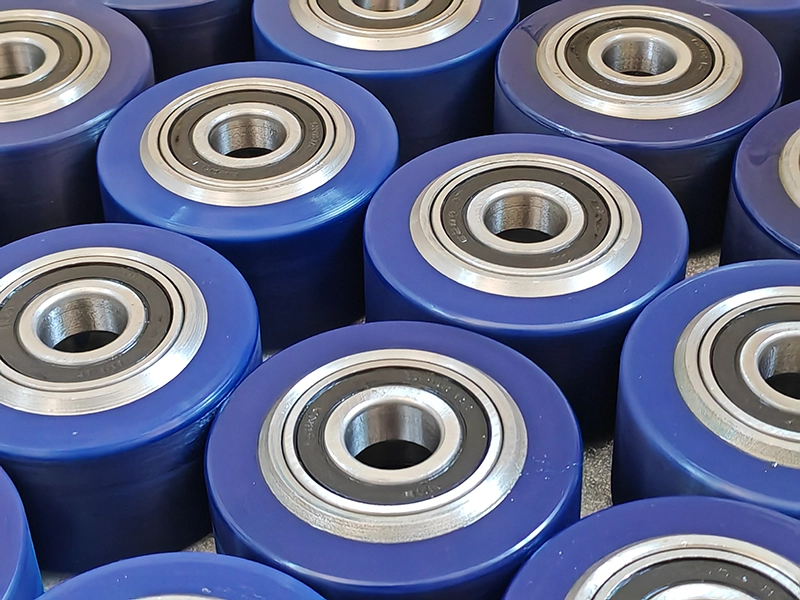

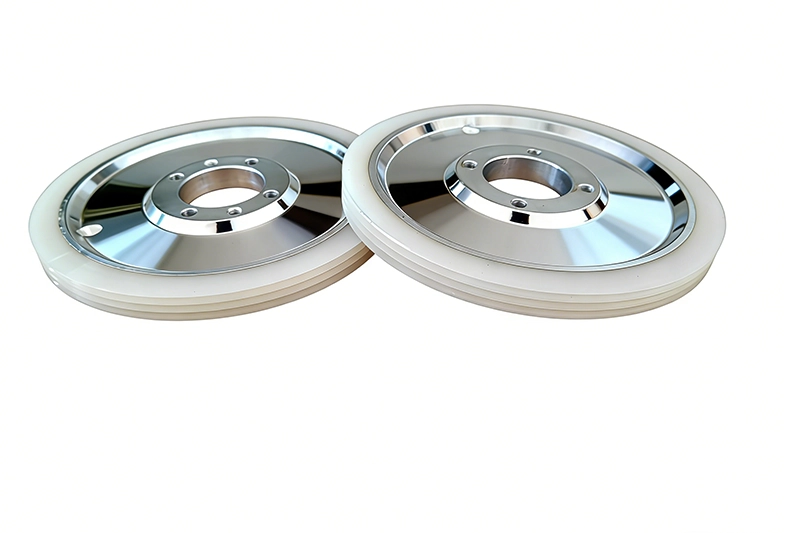

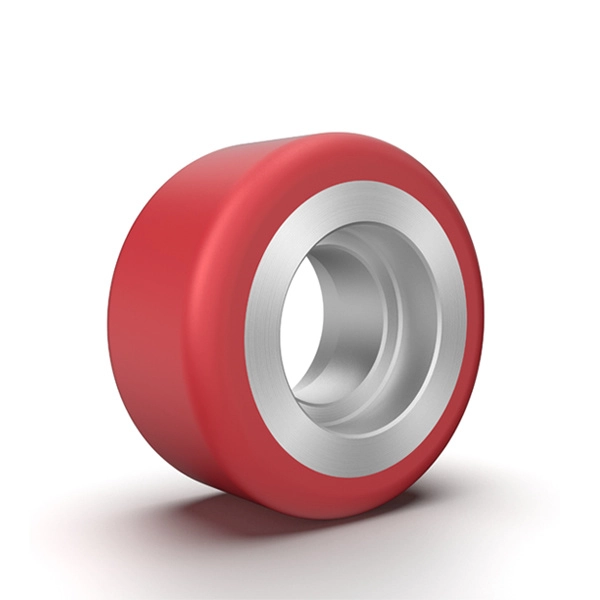

Custom Cast Urethane Covered Bearings & PU Coated Bearings Supplier

- No or small tooling cost

- PU coated wheels enable smooth, non-marking operation at high speeds.

- Urethane covered bearings minimize noise and control wear in industrial settings

- Custom options let you match bearings to your exact equipment requirements.

- Polyurethane coated bearings deliver unmatched precision for heavy-duty tasks.

INDUSTRIES SERVED: Mining, Manufacturing and Automation, Agriculture