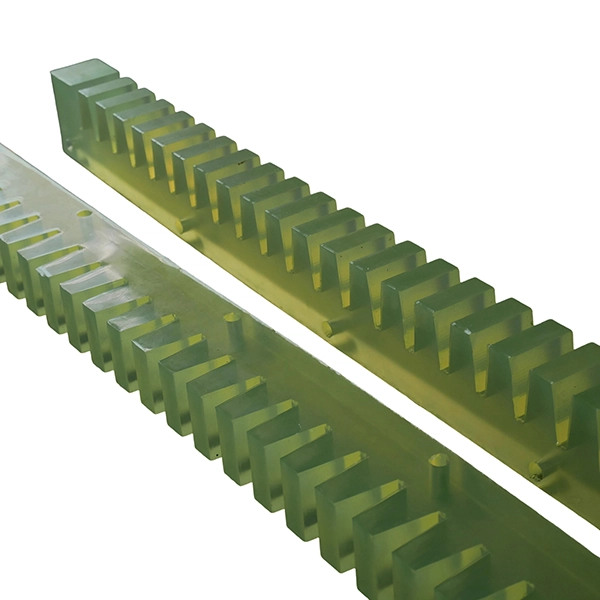

Custom Cast Polyurethane Strip – Durable Urethane Wear Strip

- As China’s PU manufacturer, we provide custom polyurethane rubber strips.

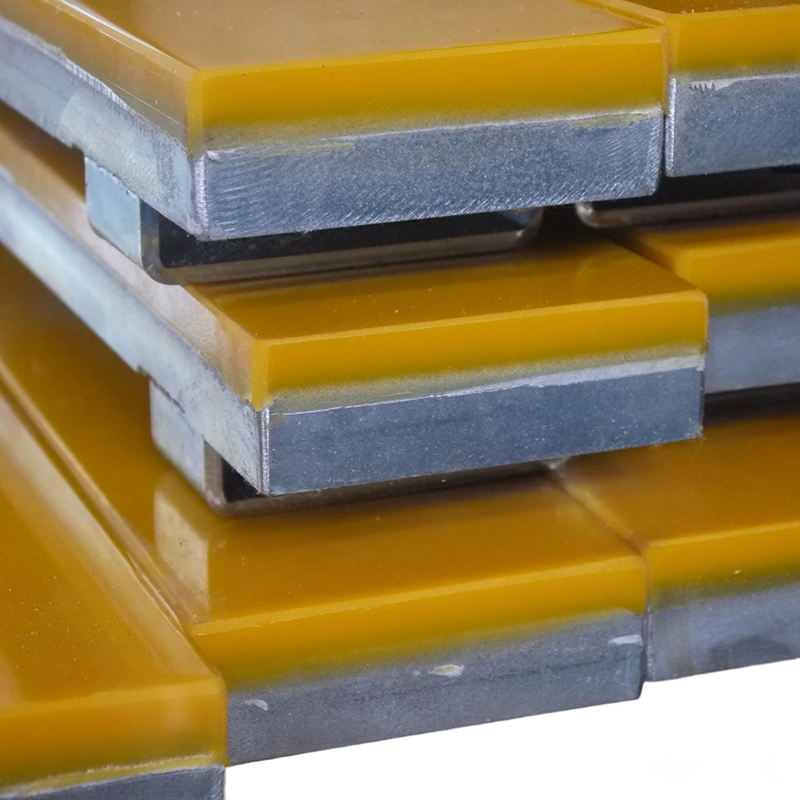

- Our PU strips are cast to near-exact sizes, cutting waste.

- They resist wear/chemicals for harsh industrial environments.

- We offer NDI-based polyurethane strips options with top wear resistance and low heat.

- We provide no or low mold costs for custom polyurethane strips.

INDUSTRIES SERVED: Automotive , Industrial Equipment, Electronics, Food Processing, Mining