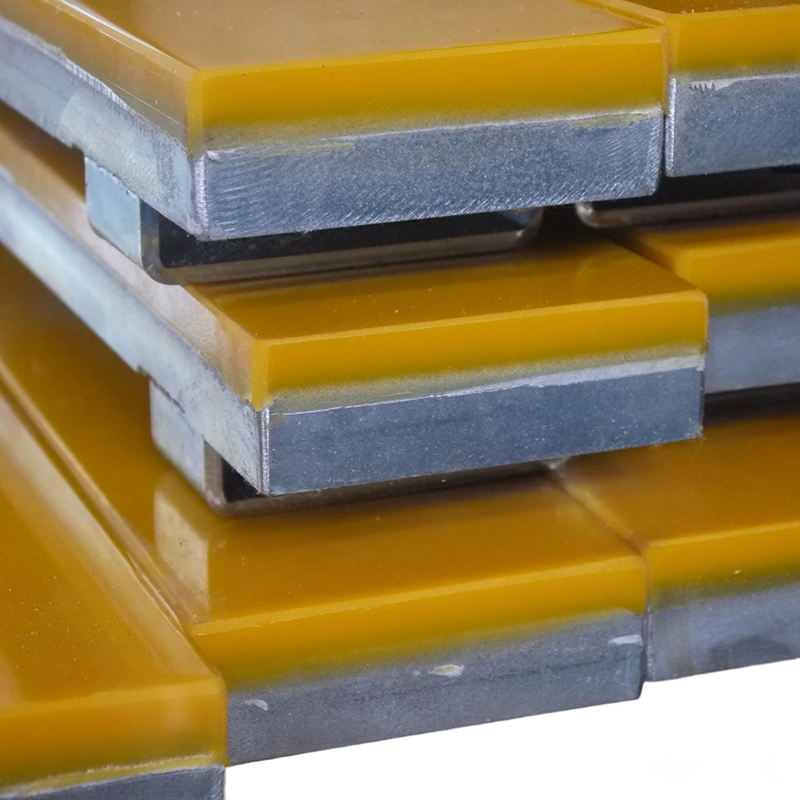

Custom Cast PU Rubber Sheets from a Leading China Supplier

- We manufacture urethane sheet for fast delivery.

- Eliminates fit problems—custom-sized to match your unique equipment specs perfectly.

- Stands up to harsh industrial wear/chemicals—avoids frequent replacement from damage.

- Prevents spacing errors in precision setups—keeps parts aligned, no costly misalignment faults.

- No or low mold costs

INDUSTRIES SERVED: Automotive , Industrial Equipment, Electronics, Food Processing, Chemical