Durable · Precise · Customized, Solving Your Application Challenges

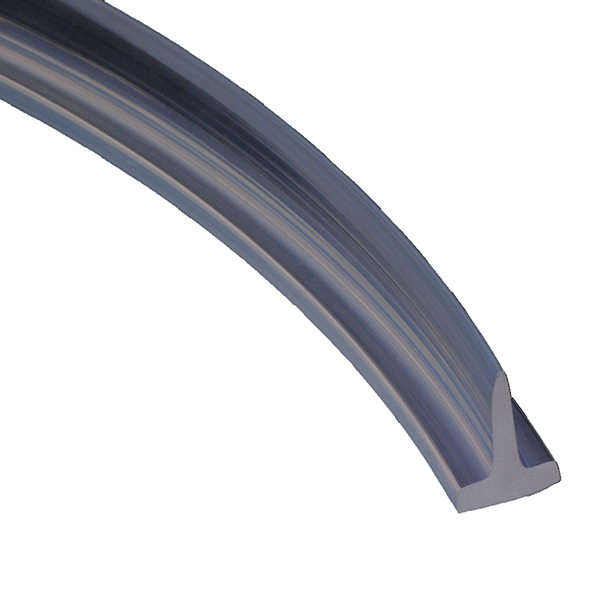

- Solid not foam, resists deformation under load

- Wear resistance 5x that of regular rubber

- Wide temperature adaptability (-40℃~80℃), no brittleness in winter, no softening in summer

- Ester-based oil-resistant / ether-based hydrolysis-resistant, FDA/RoHS compliant

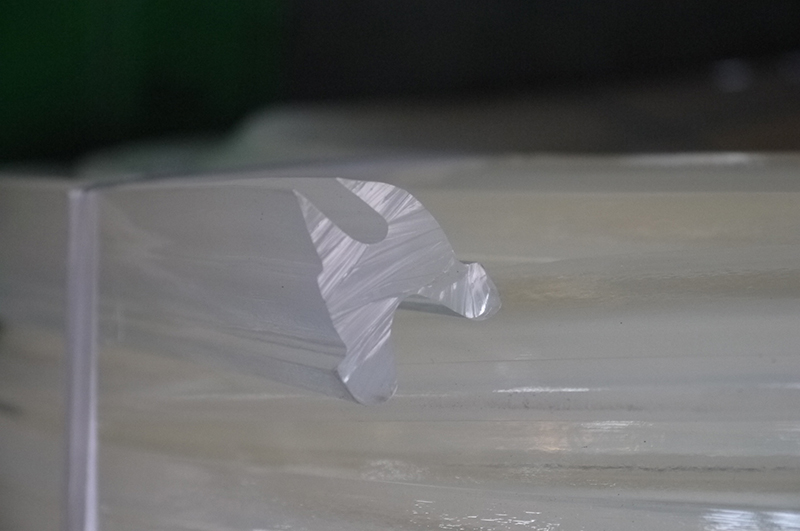

- Precision extrusion with tighy tolerance, supports 2D/3D drawing and samples customization

- 30% less replacement frequency

INDUSTRIES SERVED: Conveyor , Material Handling, Agriculture, Manufacturing & Industrial Machinery