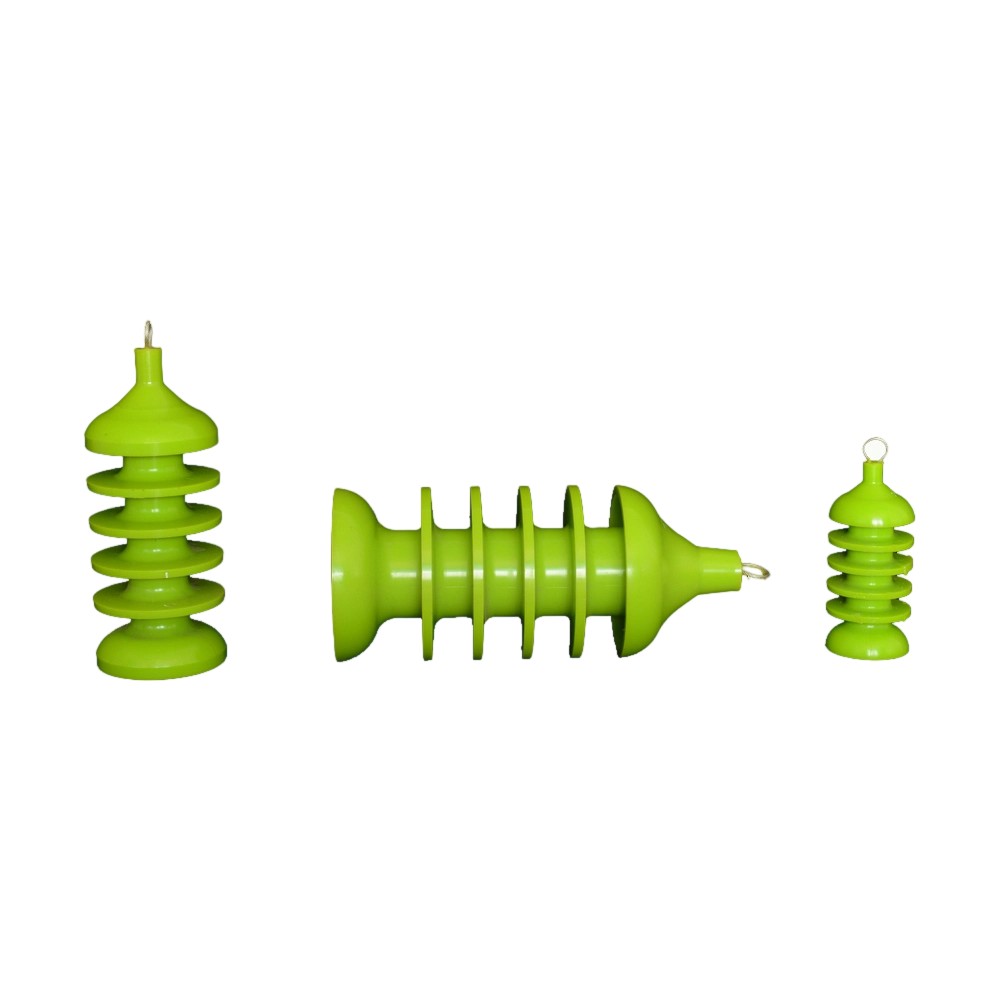

High-Performance Urethane Pigs for Efficient Pipeline Maintenance

- Cleans pipes thoroughly without scratching inner walls

- Custom-sized to fit your pipeline diameter perfectly

- Resists chemicals, wear—lasts longer than rubber pigs

- Cleans pipes thoroughly without scratching inner walls

- Custom-sized to fit your pipeline diameter perfectly

- Resists chemicals, wear—lasts longer than rubber pigs

We are a China's manufacturer of customized urethane cleaning pigs for pipeline, by using a high-performance custom casting polyurethane blend. They care designed as a solid one piece structure, and have a combination of cups and discs spaced along the body.

Our solid cast urethane pipeline cleaning pigs outperform rubber ones. They keep shape under pressure, clean debris (rust, scale, sludge) effectively, and won’t degrade in oil, gas, or water pipelines. Each pig is inspected for quality before shipping.

These Pipeline Pigs serve oil & gas, water treatment, chemical processing, and petrochemical industries. They pay important roles in maintaining pipeline flow and preventing blockages.

| Customization Parameter | Specifications | Target Equipment/Industries |

|---|---|---|

| Diameter | 2” to 48” (or custom) | Oil & gas pipelines (6”-24”), water mains (2”-12”) |

| Hardness (Shore A) | 60A (soft) to 98A (medium) to 75D (hard) | Chemical pipelines (80A–90A), water pipelines (60A–70A) |

| Design Features | Scrapers, brushes, magnets, bypass ports | Scale removal (scrapers), rust cleaning (magnets), fluid flow (bypass ports) |

| Core Material | Steel, aluminum, or hollow core | High-pressure gas pipelines (steel core), low-pressure water lines (hollow core) |

- Oil & gas pipelines for sludge and scale removal

- Water treatment pipes to clear sediment buildup

- Chemical pipelines to eliminate residue

- Petrochemical lines for pre-inspection cleaning

- Industrial process pipes to maintain flow rate

- Municipal water mains for rust and debris cleanup

1) Cleans pipes without damaging inner surfaces

2) Custom fits any pipeline diameter (2”–48”)

3) Urethane resists oils, chemicals, and extreme temperatures in pipeline

4) 50% longer lifespan than rubber cleaning pipeline pigs

5) Cold flow resistance ,Ozone resistance

- BASF urethane material used

- Quality inspection for crack, bubbles and tear for each urethane pigs

- Design and technical support

- Urethane blends resists oils, chemicals, and extreme temperatures

- Relative low tooling cost

- Fast turnaround for custom pipeline cleaning pigs orders

As they moved through metal pipelines, the friction between the straw/leather and pipe walls, or the tool’s vibration against the pipe, created a loud, high-pitched noise that sounded like a pig squealing

A urethane process pig is a specialized, durable tool made from high-performance polyurethane (urethane) used to maintain, test, or optimize pipeline operations—going beyond basic cleaning to support core industrial processes.

Yes. We are manufacturer. Welcome to visit our factory.

Yes. The process includes Share needs → design & quote → prototype (opt) → production → delivery.

We have 10 inspectors to carry out raw material inspection, process control ,first article inspection and final inspection.

We use the ERP system to execute orders, and can check the order status and expected delivery time at any time.

All of products with 3-6 months guarantee (except very frequently wearing parts).

We will response in 24 hours with solutions such as replacement or reworking.

We have dedicated personnel to sort out and maintain molds regularly.

20,000 times for compressions molds and 30,000 time for casting molds

Due to the large quantity of molds, we can keep the molds for free for 2 to 3 years even if no order.

Customers only need to pay mold cost once. We will cover the cost if molds are damaged or reach the lifespan.

get a quote